Are you trying to find the ideal aluminum alloy for your machining projects, aiming for efficiency and a high-quality finish? The right alloy makes all the difference.

For optimal machining, aluminum alloys1 like 2011, 60612, and 7075 are excellent choices, offering good chip control and surface finishing capabilities, with forged 6061 being a prime example of superior machinability.

Let's explore which aluminum alloys will serve your machining needs best.

Is aluminum 6061 good for machining?

When selecting aluminum for precision machining, you might wonder about the performance of popular alloys like 6061.

Yes, aluminum 6061, particularly in its T6 temper, is widely considered very good for machining due to its excellent balance of strength, corrosion resistance, and its ability to produce clean cuts and good surface finishes.

Aluminum alloy 6061 is a workhorse in many industries, and its suitability for machining is a significant reason for its popularity. This alloy, a combination of aluminum, magnesium, and silicon, achieves its excellent properties through heat treatment, commonly in the T6 temper. In this state, 6061 offers a remarkable blend of properties: it's strong enough for many structural applications, highly resistant to corrosion, and easily weldable. Crucially for machining operations, 6061-T6 tends to produce manageable, relatively short chips that are easily cleared from the cutting area. This contributes to smoother machining processes, reduces the risk of tool damage or workpiece scratching, and allows for a high-quality surface finish. While alloys like 2011 might be considered "freer machining" due to additives that create brittle chips, 6061-T6 provides a superior overall combination of strength, corrosion resistance, and acceptable machinability. For my clients at SWA Forging, especially those in the Middle East, this balance makes forged 6061 an ideal material for their precision-machined components.

What is the difference between forged and machined aluminum?

Understanding the distinction between "forged" and "machined" aluminum is vital for appreciating the material's journey and properties.

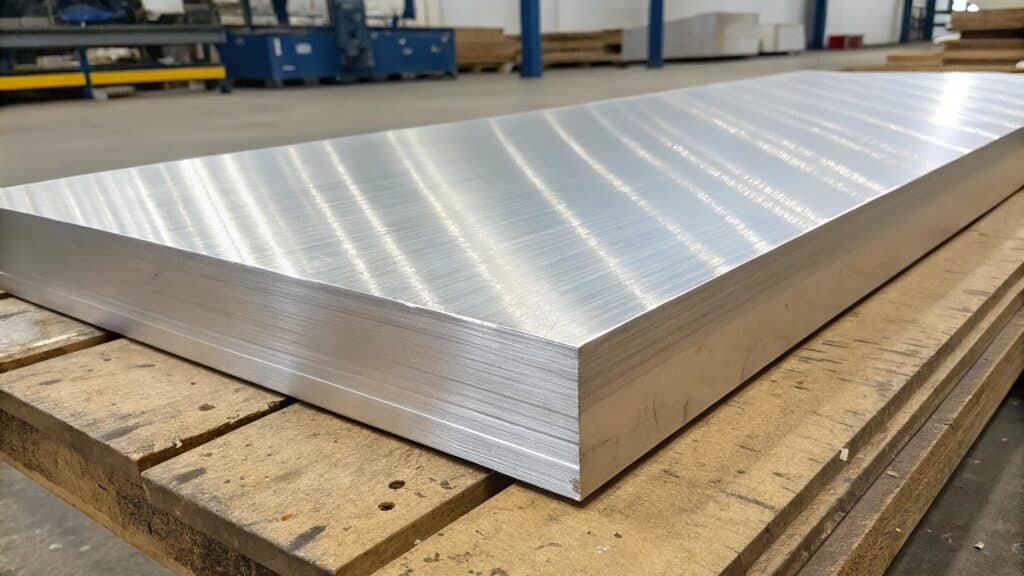

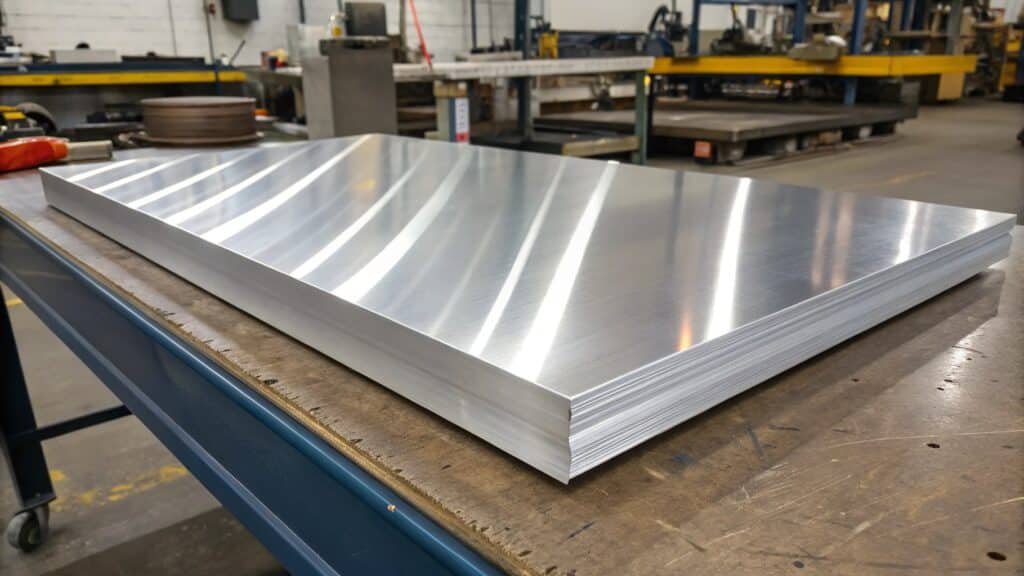

Forging shapes aluminum using pressure to improve its internal structure and strength, while machining removes material from a workpiece (which can be forged or cast) using cutting tools to achieve specific dimensions and finishes.

It's important to clarify that "forged" and "machined" refer to different manufacturing processes that can be applied to aluminum. Forging is a primary metal-forming process. It involves heating a solid piece of aluminum and then shaping it under immense pressure, typically using hammers or dies. This process rearranges the metal's internal grain structure, making it denser, stronger, and more ductile. The outcome of forging is often a component that is very close to its final shape, known as a "near-net shape," possessing superior material properties. Machining, conversely, is a subtractive manufacturing process. It uses cutting tools on machines like lathes or milling centers to remove material from a workpiece, thereby achieving precise dimensions, intricate details, and a desired surface finish. The workpiece that is being machined can come from various sources, including a forged blank, a casting, or an extrusion. Therefore, it's common for aluminum parts to be forged first to imbue them with inherent strength and structural integrity, and then machined to meet exact specifications. At SWA Forging, we specialize in producing high-quality forged aluminum, providing a superior starting material for our clients' subsequent machining operations.

What is the best aluminum for forging?

Selecting the right aluminum alloy for forging depends on the desired properties of the final component. What alloys are most suitable?

Aluminum alloys like 6061, 6082, 5083, and 7075 are commonly used for forging, each offering a unique balance of strength, formability, corrosion resistance, and weldability, with 6061 being a popular choice for its versatility.

The choice of aluminum alloy for forging is guided by the intended application and the performance characteristics required in the final part. For general-purpose applications where a good combination of strength, corrosion resistance3, and machinability is needed, 6061 is an excellent choice. Its ability to be heat-treated to achieve desirable mechanical properties makes it highly versatile. 6082 is similar to 6061, offering good strength and corrosion resistance, often preferred in structural applications where higher mechanical properties are mandated. For marine applications or environments requiring exceptional corrosion resistance and good formability, alloys from the 5xxx series, such as 5083, are excellent candidates; they contain magnesium and offer good strength without heat treatment. For high-strength applications, especially in the aerospace sector, 7075 is a top choice, offering strength comparable to some steels, though it can be more challenging to forge and machine. At SWA Forging, we frequently work with 6061 and other alloys from the 6xxx series to produce robust, high-quality forged components for our clients, balancing the demands for strength with the need for reliable manufacturing processes.

Are forged parts stronger than machined parts?

When comparing the strength of aluminum components, it's crucial to understand that "forged" and "machined" refer to different stages of manufacturing, not competing forms of material.

Forged aluminum parts are generally stronger than cast aluminum parts due to their refined grain structure and absence of defects. Machining is a process that shapes a material, and a forged part that is then machined will be stronger than a cast part that is also machined.

It's important to clarify a common misconception: "forged" describes the process of creating the material's structure, while "machined" describes how a part's final shape and dimensions are achieved. Forged parts gain their strength from the plastic deformation during the forging process, which aligns the grain structure and eliminates internal flaws. This results in superior tensile strength, yield strength, and fatigue resistance compared to cast parts, which often contain internal porosity or inconsistent grain structures. Therefore, a forged part inherently possesses a stronger material structure. When a part is machined, material is removed from a raw form to achieve precise specifications. If you take a forged aluminum blank and machine it, the resulting part will be stronger than if you took a cast aluminum blank and machined it to the same dimensions. This is because the superior material properties of the forged starting material are carried through the machining process. At SWA Forging, we provide the high-quality forged aluminum blanks that enable our clients to produce incredibly strong and reliable machined components.

Conclusion

The best aluminum for machining includes alloys like 2011, 6061, and 7075, with forged 6061 offering superior machinability and strength. Forged parts are stronger than cast parts, and machining refines these materials to final dimensions.