Are you struggling to find standard aluminum parts that perfectly fit your unique project requirements? Generic solutions can often lead to compromises.

At SWA Forging, we specialize in creating custom forged aluminum components, offering tailored solutions that perfectly match your design specifications, delivering superior performance and precision where off-the-shelf options fall short.

Discover how custom forging can elevate your projects.

Is 6061 T6 aluminum forged?

When working with aluminum, understanding the specifics of alloys like 6061 T6 is important, especially regarding its manufacturing process.

Yes, aluminum 6061 can be forged, and when it undergoes the T6 temper heat treatment, it achieves a state of enhanced strength and hardness, making forged 6061 T6 a highly sought-after material for demanding applications.

Aluminum alloy 6061 is a widely used material known for its excellent combination of properties. Forging is a primary shaping process that involves deforming solid metal under pressure. This process can be applied to 6061 aluminum to create parts with a refined grain structure and superior mechanical integrity. The "T6" designation refers to a specific heat treatment applied after forging. This process involves solution heat treating the aluminum and then artificially aging it. The result is a significant increase in strength and hardness, making 6061 T6 a robust and reliable material. Because forging creates a dense, continuous grain flow that follows the contours of the part, forged 6061 T6 offers higher tensile strength, yield strength, and fatigue resistance compared to its cast or extruded counterparts. This makes it ideal for applications where performance and durability are critical. At SWA Forging, we have extensive experience producing custom forged 6061 T6 components, meeting precise client specifications for a wide range of industries.

What are the benefits of forged Aluminium?

Understanding the advantages of forged aluminum can highlight why it's chosen for critical applications over other forms of aluminum.

Forged aluminum offers superior mechanical properties, including higher strength, improved fatigue resistance, and enhanced ductility, all due to its dense, continuous grain structure and the absence of internal defects inherent in the forging process.

The benefits of using forged aluminum are substantial and directly linked to the fundamental way it is produced. Unlike casting, where molten metal solidifies with a more random grain structure and potential for internal voids, forging shapes solid aluminum under intense pressure. This process realigns the metal's grain structure, creating a dense, homogeneous microstructure where the grains flow along the contours of the part. This refined grain structure is the primary reason forged aluminum exhibits significantly higher tensile strength, yield strength, and impact toughness. It also results in improved fatigue strength, meaning forged parts can withstand repeated stress cycles much better than cast parts. The elimination of internal voids and inconsistencies also contributes to greater ductility, allowing the material to deform more before fracturing. These superior material properties translate into components that are more reliable, durable, and capable of performing under extreme conditions. For my clients, especially those in industrial sectors who demand high performance, these inherent benefits of forged aluminum make it the preferred material for critical components, ensuring longevity and operational integrity.

What is the best aluminum for forging?

When embarking on a forging project, selecting the appropriate aluminum alloy is paramount to achieving the desired outcome. What alloys are best suited?

Aluminum alloys such as 6061, 6082, 5083, and 7075 are excellent choices for forging, each providing a unique blend of strength, formability, corrosion resistance, and weldability, with 6061 being a particularly versatile and popular option.

The selection of an aluminum alloy for forging hinges on the specific performance characteristics required in the final component. For general engineering purposes where a good combination of strength, corrosion resistance, and ease of subsequent machining is needed, 6061 stands out as an excellent choice. Its ability to be effectively heat-treated to achieve specific mechanical properties makes it highly adaptable. 6082 is another strong alloy, often used in structural applications where it delivers higher mechanical properties than 6061 and maintains good corrosion resistance. For applications demanding exceptional corrosion resistance and good formability, particularly in marine environments, alloys from the 5xxx series, such as 5083, are ideal; these alloys achieve their strength through the addition of magnesium and do not require heat treatment. For applications requiring the highest strength, especially in the aerospace industry, 7075 is a premier alloy, offering strength comparable to some steels, although it can be more challenging to forge and machine. At SWA Forging, we frequently produce high-quality forged components from 6061 and other 6xxx series alloys, catering to clients who require a robust balance between performance and manufacturing efficiency.

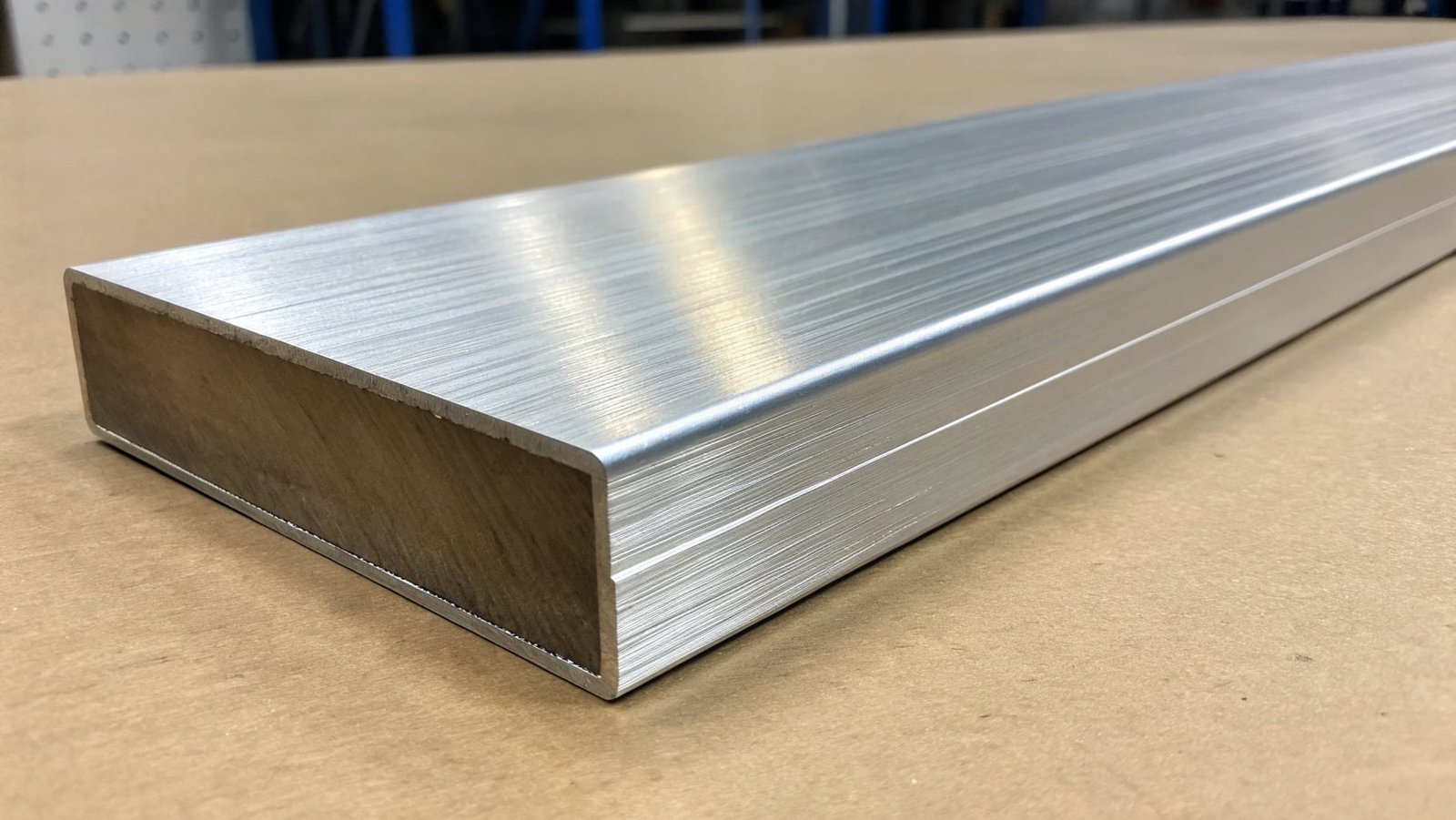

What is the difference between drawn and extruded aluminum?

Understanding the distinctions between drawn and extruded aluminum is important for selecting the right material processing method for your needs.

Extrusion shapes aluminum by forcing heated material through a die to create a profile, while drawing further refines the shape and improves mechanical properties by pulling the extruded material through a die or over a mandrel.

Extrusion and drawing are both metal-forming processes used for aluminum, but they achieve different results. Extrusion is a primary process where heated aluminum alloy is pushed or "extruded" through a die that has a specific cross-sectional shape. This results in a long, continuous profile, such as bars, tubes, or complex shapes. Extrusion is highly versatile for creating intricate cross-sections that would be difficult or impossible to achieve with other methods like rolling. Drawing, on the other hand, is typically a secondary process. It involves pulling an already formed shape, such as an extruded tube or rod, through a die with a smaller opening or over a mandrel. This process reduces the diameter, thins the walls of tubes, and increases the length of the product. Crucially, drawing also work-hardens the aluminum, which refines the grain structure and improves its mechanical properties, such as tensile strength and hardness. While extrusion creates the initial shape, drawing further improves its dimensional accuracy and enhances its material strength. This is different from forging, which reshapes solid metal under pressure to optimize its internal grain structure from the start.

Conclusion

Custom forged aluminum, particularly alloys like 6061 T6, offers superior properties for tailored solutions, distinct from standard extruded or drawn products.