Are you curious about what makes aluminum alloy forgings stand out? Understanding their unique traits is key to choosing the right material for your needs.

Aluminum alloy forgings are characterized by their high strength-to-weight ratio, excellent corrosion resistance, good ductility, and fine grain structure, making them ideal for demanding applications across various industries.

When clients inquire about the characteristics of aluminum alloy forgings, they're looking for a clear picture of the material's capabilities. My aim is to break down these properties in a way that directly relates to their applications, whether they are traders or manufacturers.

What is the aluminium alloy for forging?

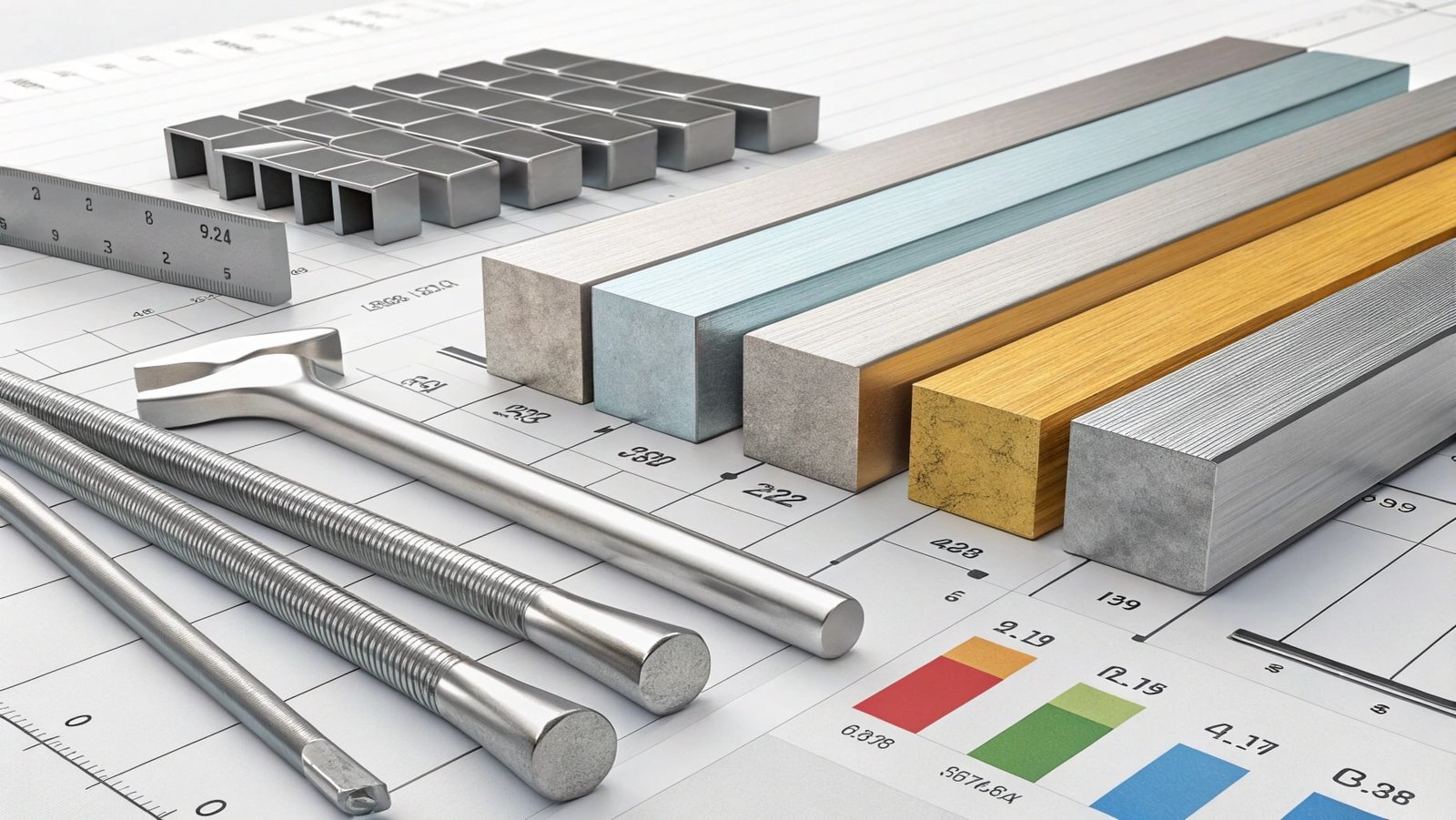

Selecting the right aluminum alloy is critical for successful forging, as each alloy possesses unique properties that influence its forgeability and the performance of the final product.

Aluminum alloys commonly used for forging include the 6xxx series1 (e.g., 6061) for its balance of strength and corrosion resistance, and the 7xxx series2 (e.g., 7075) for its very high strength, often used in aerospace applications. Other series like 2xxx and 5xxx are also utilized for specific performance requirements.

The question of "which aluminum alloy for forging" is one I answer frequently. The choice depends heavily on the end-use application, the required mechanical properties, and the complexity of the part being forged. At SWA Forging, we carefully select alloys to ensure optimal results for our clients.

Here's a look at common alloys and their suitability for forging:

- 6xxx Series (e.g., 6061, 6082): These are perhaps the most versatile and widely used alloys for forging. They contain magnesium and silicon, offering a good combination of medium to high strength, excellent corrosion resistance3, good weldability, and responsiveness to heat treatment. 6061 is a workhorse alloy for many general engineering and structural applications.

- 7xxx Series (e.g., 7075, 7050): These alloys are known for their exceptionally high strength, often comparable to steel. They contain zinc as the primary alloying element, along with magnesium and copper. 7075 is particularly favored in the aerospace industry for its strength-to-weight ratio. They require careful control during forging due to their sensitivity to processing temperatures.

- 2xxx Series (e.g., 2024): These alloys, strengthened by copper, offer high strength and good fatigue resistance, making them suitable for aircraft structures. However, they have lower corrosion resistance than 6xxx or 5xxx series alloys and require protective coatings.

- 5xxx Series (e.g., 5083, 5086): These alloys, strengthened by magnesium, provide excellent corrosion resistance, good weldability, and moderate strength. They are often used in marine applications or where exposure to corrosive environments is a concern.

The selection process involves balancing strength requirements, cost, corrosion resistance, and ease of manufacturing.

What are the characteristics of forging process?

The forging process itself imparts distinct characteristics to the metal, setting it apart from other manufacturing methods.

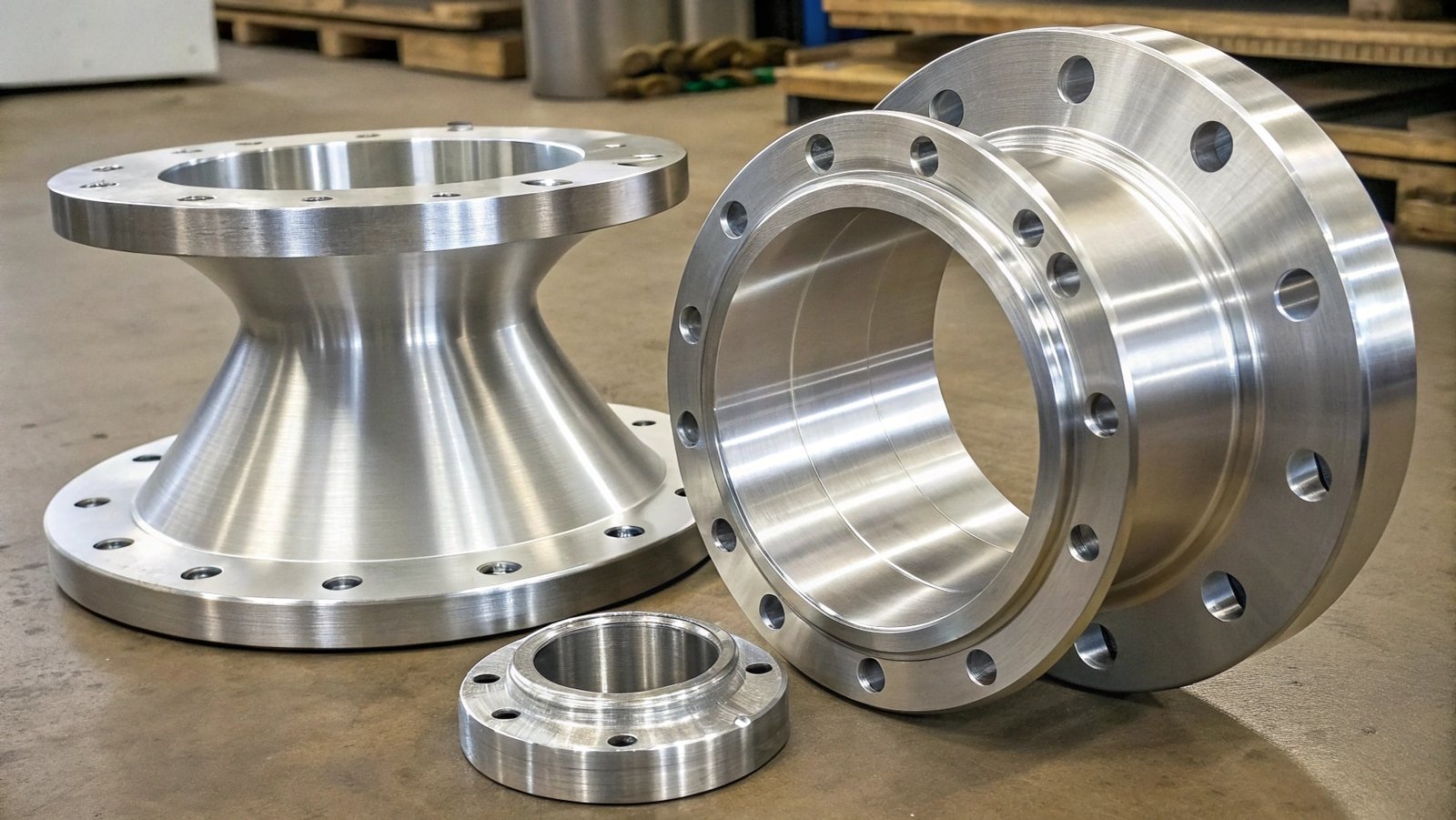

The forging process is characterized by its ability to refine the grain structure of metals, leading to enhanced mechanical properties such as increased strength, toughness, and fatigue resistance. It also allows for the creation of complex shapes with tight tolerances and uniform material properties.

When we discuss the characteristics of the forging process, we're talking about the inherent advantages that result from how the metal is shaped. It’s this transformative nature of forging that makes the resulting components so reliable and high-performing, a key selling point for our clients.

Here are the defining characteristics of the forging process:

- Grain Structure Refinement: Perhaps the most significant characteristic is the way forging aligns the metal's grain structure. As the metal is deformed, the grains elongate and align themselves along the flow lines of the workpiece. This creates a continuous grain flow without breaks, unlike in casting where grains can be more random.

- Enhanced Mechanical Properties: The refined grain structure directly translates to improved mechanical properties. Forgings typically exhibit higher tensile strength, yield strength, ductility, and fatigue strength compared to parts made by other methods from the same alloy.

- Dimensional Accuracy and Detail: Through the use of precisely machined dies, forging can produce parts with complex shapes and tight dimensional tolerances, often reducing the need for secondary machining operations.

- Internal Integrity: The process helps to eliminate internal voids, porosity, and inclusions that can be present in cast or wrought materials, leading to a more robust and defect-free product.

- Material Efficiency: Forging often starts with a precisely cut piece of raw material, and the shaping process minimizes material waste, contributing to cost-effectiveness, especially for high-volume production.

These inherent characteristics of the forging process are why it remains a preferred method for manufacturing critical components across various demanding industries.

What are the properties of forged material?

The properties of forged material are a direct result of the forging process itself, giving it distinct advantages over other manufacturing techniques.

Forged materials possess superior mechanical properties, including high tensile strength, excellent toughness, good ductility, and enhanced fatigue resistance. This is due to the refined and directional grain structure achieved during the shaping process.

Clients often ask about the "properties" of forged material because they need to know if it can withstand the stresses and demands of their specific applications. The properties we achieve through forging are precisely what give our clients confidence in the performance and longevity of our products.

The key properties of forged materials include:

- High Strength and Toughness: The process of working the metal under heat and pressure realigns the internal grain structure. This creates a stronger, more ductile material that can withstand higher loads without deforming or fracturing. Toughness, the ability to absorb energy before fracturing, is also significantly improved.

- Excellent Fatigue Resistance: Due to the continuous grain flow, forged parts are more resistant to fatigue failure. Repeated stress cycles are less likely to initiate cracks compared to materials with interrupted grain structures.

- Good Ductility: While strong, forged materials also retain good ductility, meaning they can be deformed without breaking. This is important for applications where the material might undergo bending or impact.

- Dimensional Accuracy and Integrity: Forging allows for precise shaping, resulting in parts with tight tolerances and good surface finish. The process also minimizes internal defects like porosity and voids, ensuring structural integrity.

- Uniformity: The grain structure and mechanical properties are generally more uniform throughout a forged part compared to other methods, leading to more predictable performance.

These properties are why forged components are often specified for critical applications where failure is not an option.

What is forged aluminum made of?

Understanding what forged aluminum is made of requires looking at both the base material and the process that transforms it.

Forged aluminum is made from high-quality aluminum alloys, typically those containing elements like magnesium, silicon, copper, or zinc. These alloys are heated and then shaped by compressive forces, usually within dies, which refines their grain structure and enhances their mechanical properties.

When people ask "what is forged aluminum made of," they are asking about the composition of the material itself. It’s not just about aluminum; it’s about the specific alloy that gives it its unique properties. As a manufacturer, the precise alloy selection is fundamental to meeting client specifications.

Here’s what forged aluminum is made of:

- Aluminum Alloy: The base material is aluminum, but it is almost always an alloy. Pure aluminum is too soft for most structural applications. Alloys are created by adding other elements to improve strength, hardness, corrosion resistance, or other properties.

- Alloying Elements: Common alloying elements include:

- Magnesium (Mg) and Silicon (Si): These are key components of the 6xxx series alloys (like 6061), which are very popular for forging due to their balanced properties.

- Zinc (Zn): Often found in the 7xxx series alloys (like 7075), which provide very high strength.

- Copper (Cu): Used in the 2xxx series alloys for high strength, particularly in aerospace.

- Manganese (Mn): Found in the 3xxx series for moderate strength and formability.

- The Forging Process: The "made of" also refers to the transformation process. The aluminum alloy is heated to a specific temperature and then forced into a desired shape using dies. This shaping process is what defines it as a "forging." It's this combination of alloy composition and manufacturing method that yields the superior properties.

So, forged aluminum is essentially a precisely formed component made from a carefully selected aluminum alloy, processed through a method that enhances its inherent material characteristics.

Conclusion

Aluminum alloy forgings offer high strength, corrosion resistance, and durability due to their refined grain structure, achieved through specific forging processes using alloys like 6061 and 7075.