Confused about which aluminum alloy is best for your high-performance needs? Understanding the specific properties of alloys like 2024 is crucial for making the right choice.

2024 aluminum alloy is known for its exceptional strength, good fatigue properties, and moderate corrosion resistance, making it a prime choice for aerospace and high-stress applications, though it requires careful handling due to its sensitivity to temperature.

When clients discuss their projects, especially those in demanding sectors like aerospace, the focus often shifts to high-strength materials. 2024 aluminum alloy is a prime example, and understanding its specific characteristics is key to specifying it correctly for forging.

What are the characteristics of 2024 aluminum?

2024 aluminum alloy stands out due to a specific set of properties that make it suitable for applications where strength and performance are paramount.

2024 aluminum alloy1 is characterized by its very high strength-to-weight ratio, excellent fatigue resistance, and good machinability. However, it has moderate corrosion resistance and is susceptible to stress corrosion cracking, often requiring protective coatings or treatments.

The defining traits of 2024 aluminum are what make it a go-to material for critical components. For our clients, especially those in industries like aerospace, understanding these characteristics helps them appreciate why this alloy is chosen and what considerations are needed during manufacturing and use.

Here are the key characteristics of 2024 aluminum:

- High Strength: Its primary advantage is its very high tensile and yield strength, especially after heat treatment. It achieves strengths comparable to many steels.

- Excellent Fatigue Strength: 2024 exhibits superior resistance to fatigue, meaning it can withstand repeated stress cycles without failing. This is crucial for components that experience cyclic loading, like aircraft wings.

- Good Machinability: It can be machined effectively to achieve precise dimensions and complex shapes, which is important for intricate parts.

- Moderate Corrosion Resistance: While it has decent corrosion resistance2 in milder environments, it is more susceptible to corrosion and stress corrosion cracking than alloys like the 6xxx series, particularly in chloride environments. This often leads to its use with protective cladding or coatings.

- Heat Treatable: 2024 is a precipitation-hardenable alloy. It can be strengthened significantly through heat treatment (solution heat treatment followed by aging), which is essential for achieving its peak mechanical properties.

- Not Weldable by Conventional Methods: Due to its tendency to lose strength in the heat-affected zone, 2024 is generally not recommended for fusion welding. Resistance welding techniques are sometimes used.

These characteristics make 2024 aluminum a preferred material for demanding applications where high performance and lightweight are critical factors.

What is the difference between 2014 and 2024 aluminum?

Both 2014 and 2024 are high-strength aluminum alloys from the 2xxx series, but they have subtle differences in their composition and properties that influence their applications.

The main difference between 2014 and 2024 aluminum alloys lies in their alloying elements and resulting properties. 2014 typically has a higher copper content and is often preferred for forging and machining due to its superior hot-working capabilities and strength at elevated temperatures, while 2024 is known for its higher fatigue strength and good ductility at room temperature, making it common in aircraft structures.

When clients compare different aluminum alloys, it’s important to highlight the nuances. Both 2014 and 2024 are high-strength options, but their specific applications can differ based on factors like operating temperature and the manufacturing process. Understanding these differences helps us guide clients to the best material for their forging needs.

Here’s a comparative look:

- Composition:

- 2014: Contains higher copper content than 2024. It also typically includes silicon and magnesium.

- 2024: Contains copper, magnesium, and manganese. The specific balance of these elements contributes to its characteristic properties.

- Strength: Both alloys offer very high strength. 2014 generally exhibits higher strength, particularly at elevated temperatures compared to 2024.

- Forgeability and Machinability: 2014 is often considered to have better hot-working capabilities and machinability than 2024, especially at higher temperatures. This makes it a popular choice for forging complex parts.

- Fatigue Strength: 2024 generally has superior fatigue strength and ductility at room temperature compared to 2014.

- Corrosion Resistance: Both alloys have moderate corrosion resistance and are susceptible to stress corrosion cracking. They often require protective coatings.

- Applications:

- 2014: Commonly used for structural aircraft components that experience high temperatures, forging stock, heavy-duty truck structures, and high-strength screw machine parts.

- 2024: Widely used for aircraft structures, particularly skins, fuselage components, wing structures, and high-speed railway cars where fatigue resistance and strength at ambient temperatures are critical.

The choice between 2014 and 2024 often comes down to whether the application prioritizes elevated temperature strength and forgeability (2014) or room-temperature fatigue life and ductility (2024).

Is 2024 aluminum machinable?

Yes, 2024 aluminum alloy1 is known for its good machinability, which is one of the reasons it's widely used in precision applications.

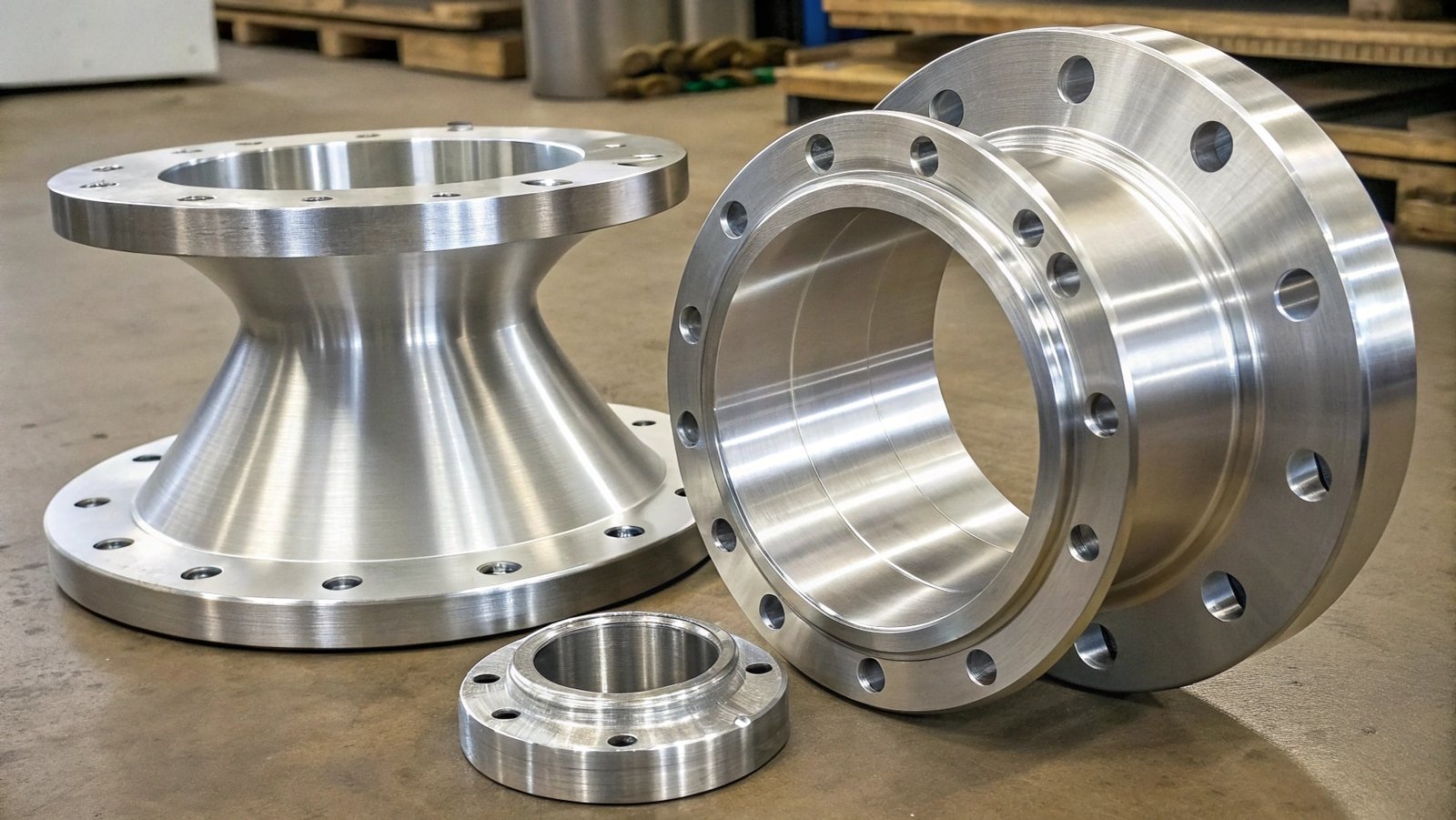

2024 aluminum alloy is considered to have good machinability. Its high strength and the presence of copper allow it to be machined effectively with appropriate tooling and cutting parameters, producing good surface finishes and tight tolerances.

Machinability is a significant factor for many of our clients, especially those involved in precision manufacturing or secondary operations after forging. Knowing that 2024 can be machined reliably is a key advantage when specifying this high-strength alloy for their parts.

Here’s why 2024 aluminum machines well:

- Chip Formation: Due to its composition, 2024 tends to form chips that are manageable rather than gummy or stringy, which makes for cleaner cuts and easier chip removal.

- Heat Treatment Effects: While heat treatment increases its strength, it also affects its machinability. In its hardened (T4 or T6) tempers, it can be machined effectively.

- Tooling and Speeds: Like any alloy, optimal machining requires the use of sharp, high-quality cutting tools and appropriate cutting speeds, feed rates, and coolants. Using carbide or high-speed steel tooling is common.

- Surface Finish: With proper machining techniques, 2024 aluminum can achieve excellent surface finishes, which is critical for components that require precise dimensions or smooth contact surfaces.

Its good machinability means that complex parts forged from 2024 aluminum can often be finished to exact specifications without excessive difficulty or cost.

What is the best aluminum alloy for forging?

The "best" aluminum alloy for forging isn't a single answer; it depends entirely on the specific application and its requirements.

The best aluminum alloy for forging depends on the application's needs, but generally, the 6xxx series (like 6061) offers an excellent balance of strength, corrosion resistance, and forgeability for general purposes, while the 7xxx series (like 7075) is superior for maximum strength, particularly in aerospace, and the 2xxx series offers high strength and fatigue resistance.

Choosing the "best" aluminum alloy is a question that requires careful consideration of many factors. It’s not about one alloy being universally superior, but rather which alloy’s properties best match the demands of the final forged part and its operating environment.

Here’s a breakdown of common choices and why they might be considered "best" for certain scenarios:

- For General Purpose and Balanced Properties: 6xxx Series (e.g., 6061):

- Why it's often "best": Excellent combination of moderate strength, good corrosion resistance, good weldability, and ease of forming. It’s versatile and cost-effective for a wide range of applications. Its forgeability is also very good.

- For Maximum Strength (Aerospace, High-Stress): 7xxx Series (e.g., 7075):

- Why it's often "best": If the absolute highest strength-to-weight ratio is needed, especially for structural aircraft components, 7075 is often the top choice. It offers strength approaching that of some steels.

- For High Fatigue Strength and Strength at Elevated Temperatures: 2xxx Series (e.g., 2024, 2014):

- Why it's often "best": 2024 is chosen for its excellent fatigue life, crucial for aircraft wings and structures. 2014 is preferred when higher strength at elevated temperatures and better forgeability are key.

- For Excellent Corrosion Resistance and Weldability: 5xxx Series (e.g., 5083):

- Why it's often "best": If corrosion resistance in harsh environments (like marine applications) is the primary concern, alloys like 5083 are excellent. They have good strength and are easily welded but are not heat-treatable.

Ultimately, the "best" alloy is the one that meets the specific performance criteria, manufacturing process, and cost targets for a given forged component.

Conclusion

2024 aluminum alloy offers exceptional strength and fatigue resistance, ideal for aerospace. While 2014 is similar, it excels in elevated temperature strength and forgeability. Both are machinable, but the "best" alloy depends on the specific application's requirements.