Are you wondering about the best forging method for your large aluminum components? Understanding the differences between open die and closed die forging1 is key to choosing the right process for your needs.

Open die forging offers flexibility and is suitable for large, simple shapes, while closed die forging provides higher precision and detail for complex parts, each with distinct advantages and limitations for manufacturing large components.

When clients discuss their requirements for large aluminum components, the question of which forging method to use is fundamental. At SWA Forging, we often explain the nuances of open die versus closed die forging, as the choice impacts everything from design flexibility to final part quality and cost.

What are the advantages of open die forging over closed die forging?

Open die forging offers unique benefits, particularly when dealing with custom or large-scale aluminum components where flexibility is paramount.

The main advantages of open die forging2 over closed die forging include greater flexibility in shaping large or irregularly shaped parts, lower tooling costs, and the ability to produce parts with simpler geometries more economically, making it ideal for custom orders and prototypes.

Clients often want to know why one forging method might be preferred over another. Open die forging's advantages lie in its adaptability, especially when dealing with custom-designed, large-volume pieces or when tooling costs need to be managed.

Here are the key advantages of open die forging:

- Flexibility and Customization: Open die forging uses relatively simple dies (often flat or with basic contours). This allows for significant manipulation of the workpiece shape by applying force repeatedly and rotating the material. This is ideal for creating custom-sized rings, discs, bars, and shafts that don't conform to a single, complex shape.

- Lower Tooling Costs: Compared to closed die forging, which requires highly precise, custom-made dies that fully enclose the workpiece, open die forging uses simpler, less expensive tooling. This makes it more cost-effective for smaller production runs, prototypes, or unique, large components.

- Economical for Large Parts: For very large or heavy parts, the cost of creating a closed die can be prohibitive. Open die forging allows for the gradual shaping of large pieces of metal without the need for massive, intricate dies.

- Material Grain Refinement: Like closed die forging, open die forging also refines the grain structure of the aluminum alloy, leading to improved mechanical properties such as strength and toughness throughout the entire bulk of the material.

- Suitable for Various Shapes: It's well-suited for producing round discs, rings, blocks, shafts, and plates, often with simple contours.

These advantages make open die forging a highly valuable process for many custom and large-scale aluminum component needs.

What is closed die forging primarily used for?

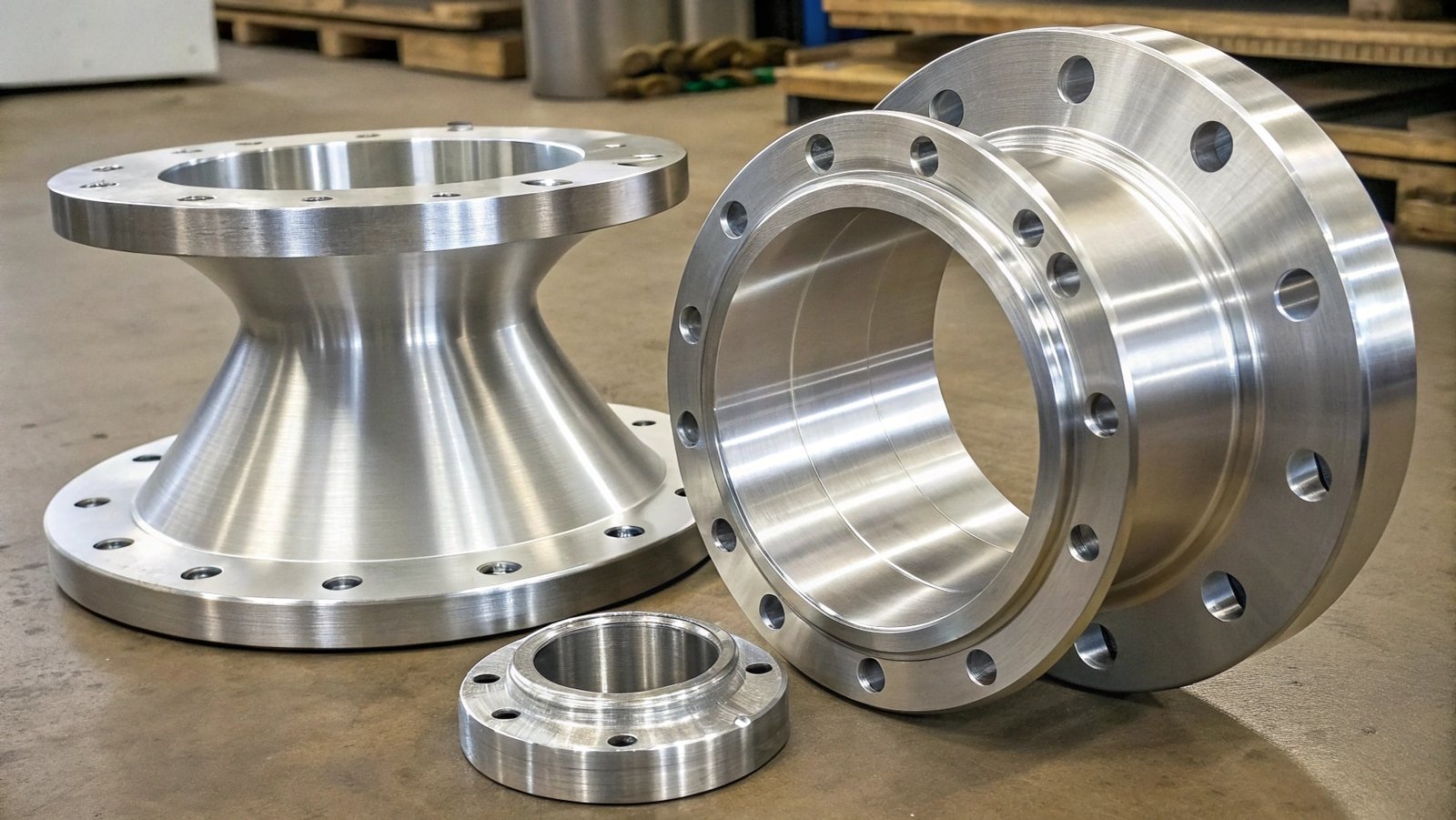

Closed die forging, also known as impression die forging, is a highly precise manufacturing process used to create parts with complex shapes and intricate details.

Closed die forging is primarily used for producing high-volume, complex-shaped metal components with tight dimensional tolerances and excellent surface finish, commonly found in industries like automotive, aerospace, and defense where precision and uniformity are critical.

When we discuss forging methods with clients, it’s important to highlight what each process excels at. Closed die forging is all about precision and repeatability, making it the go-to for many specialized components that require intricate geometries and high performance.

Here's what closed die forging is primarily used for:

- Complex Geometries: The impression in the dies precisely shapes the metal, allowing for the creation of intricate forms, features like bosses, ribs, and undercuts, which would be difficult or impossible to achieve with open die forging.

- High-Volume Production: Once the expensive dies are created, the closed die process is highly efficient for producing large quantities of identical parts with minimal variation. This makes it ideal for mass-produced items.

- Precision and Tight Tolerances: The enclosed dies guide the material flow precisely, resulting in parts with very accurate dimensions and excellent surface finishes, often reducing the need for subsequent machining.

- Enhanced Material Properties: Similar to open die forging, closed die forging also refines the grain structure of the metal, aligning it with the contours of the die. This leads to superior strength, ductility, and fatigue resistance compared to casting or machining from raw stock.

- Critical Components: It is extensively used for critical components in industries such as:

- Automotive: Connecting rods, crankshafts, gears, suspension parts.

- Aerospace: Turbine components, structural aircraft parts, landing gear components.

- Defense: Components for weapons, vehicles, and aircraft.

- Industrial Machinery: Gears, levers, and specialized machine parts.

The ability to produce complex, high-quality parts consistently and in large volumes makes closed die forging an indispensable manufacturing technique for many advanced industries.

Is open die forging particularly suitable to produce parts?

Yes, open die forging is particularly suitable for producing specific types of parts, especially those that are large, custom-sized, or have simpler, more uniform shapes.

Open die forging is particularly suitable for producing large, custom-sized components such as rings, discs, shafts, blocks, and bars. Its flexibility in shaping and lower tooling costs make it ideal for producing parts with simpler geometries, prototypes, and when material properties need to be enhanced throughout a large piece of metal.

Clients often ask about the suitability of different forging methods for their specific parts. Open die forging excels when the need is for large, custom pieces that don't require the intricate detail or high-volume repeatability of closed die forging. Its adaptability is a significant advantage.

Here’s why open die forging is suitable for certain parts:

- Large Diameter Rings and Discs: This is a core application. For example, large industrial rings used in machinery, pipelines, or pressure vessels can be efficiently produced using open die forging.

- Shafts and Bars: Long, cylindrical shafts or bars with specific cross-sectional requirements can be made by drawing and elongating the material through successive forging operations.

- Custom-Sized Blocks and Plates: When specific dimensions or slightly contoured shapes are needed for large metal pieces, open die forging provides the necessary flexibility without the high cost of custom complex dies.

- Prototypes and Low-Volume Production: For new product development or when only a few large parts are needed, the lower tooling investment of open die forging makes it a much more economical choice than developing custom closed dies.

- Achieving Through-Hardening: The process allows for the mechanical properties to be enhanced throughout the entire bulk of the large component, ensuring uniform strength and toughness.

The suitability of open die forging really shines when dealing with the scale and customization required for many large industrial components.

What are the limitations of closed die forging?

While closed die forging offers precision and efficiency for complex parts, it does have certain limitations that clients should be aware of.

The primary limitations of closed die forging include high tooling costs, a longer lead time for die production, less flexibility for design changes once dies are made, and potential difficulty in achieving internal features or very large, simple shapes compared to open die forging.

Understanding the drawbacks of any manufacturing process is as important as knowing its strengths. For closed die forging, these limitations often revolve around the upfront investment and lack of flexibility, which are critical considerations for our clients when planning their production.

Here are the key limitations of closed die forging:

- High Tooling Costs: The most significant limitation is the expense of designing and manufacturing the custom dies. These dies must be incredibly precise and robust to withstand the immense pressures involved, making them a substantial upfront investment.

- Longer Lead Times: The creation of these complex dies can take a considerable amount of time, from design and machining to testing. This means that the start of production can be delayed compared to open die forging, where tooling is simpler.

- Lack of Flexibility: Once dies are produced, they are fixed to a specific shape. Making design changes to the part often requires designing and manufacturing new dies, which is costly and time-consuming. This makes it less ideal for rapid prototyping or when design iterations are frequent.

- Size and Shape Restrictions: While it can produce complex shapes, closed die forging can become impractical or prohibitively expensive for extremely large or very simple bulk shapes. For very large parts or those with very simple geometries (like long shafts), open die forging is often more cost-effective and feasible.

- Surface Finish Limitations for Internal Cavities: While the external surfaces are precisely shaped, creating complex internal features solely through forging can be challenging and may still require secondary machining.

These limitations mean that closed die forging is best suited for high-volume production of complex parts where the upfront tooling investment is justified by the efficiency and quality of the final product.

Conclusion

Open die forging excels in flexibility and cost-effectiveness for large, simple aluminum components, while closed die forging offers precision and high-volume output for complex parts, but with higher tooling costs and less design flexibility.