You choose a corrosion-resistant alloy, but your components still fail prematurely in saltwater or chemical settings. This causes costly shutdowns, damages your reputation, and puts

You choose a corrosion-resistant alloy, but your components still fail prematurely in saltwater or chemical settings. This causes costly shutdowns, damages your reputation, and puts

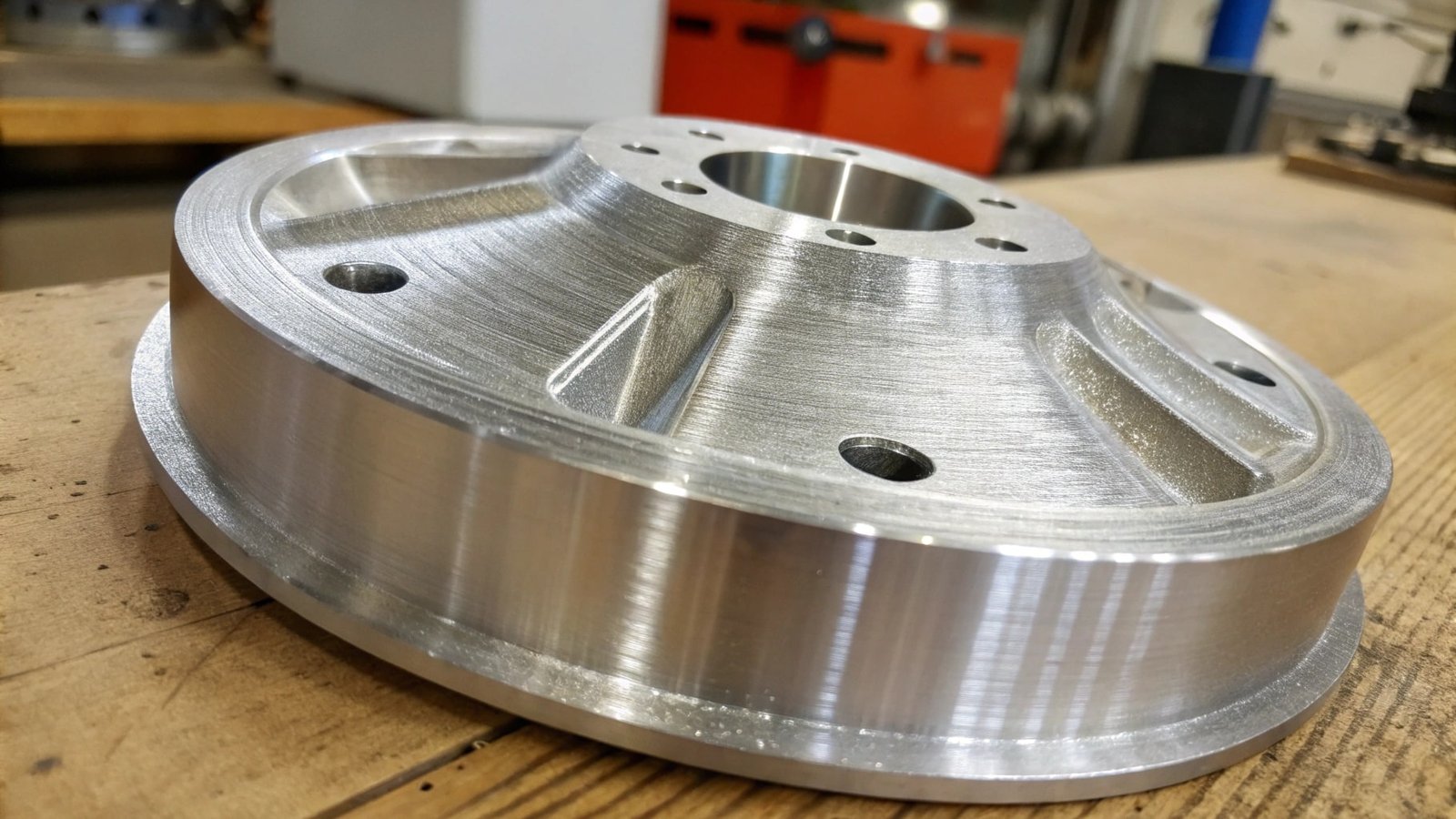

You machine a part from 6061 plate1, expecting strength, but it fails under stress. These unexpected failures are costly and damage your reputation for reliability,

You need to reduce the weight of a critical component, but you’re worried that switching from steel to aluminum will compromise its strength and integrity,

You machine a critical component from an extruded aluminum tube, believing it is strong and reliable. But under pressure or torque, a crack forms along

You order 7075 aluminum1 bar for its high strength, but your complex machined parts fail during testing or in the field. You’ve paid a premium

You source custom aluminum tubes1 for your critical machined parts, expecting consistent quality. But you still face issues with porosity and structural weakness, leading to

You need a hollow aluminum form for your machined parts and grab Schedule 40 pipe. But when subjected to real-world stress, these parts fail, revealing

You specify high-strength aluminum bar for your parts, expecting top performance. Yet, they unexpectedly crack under multi-axial loads, forcing costly redesigns and damaging your reputation

You build complex, mission-critical parts from high-strength 7075-T6 sheets1. But you rely on welds and fasteners, accepting that every single joint is a potential point

You machine complex parts from high-strength aluminum tubing1, assuming the material’s superior properties transfer directly to your component. But you still experience unexpected failures at

You’re machining parts from solid aluminum bars, especially when you need a hollow center. You accept deep-hole drilling as a necessary evil, watching valuable material

You specify expensive, advanced alloys to reduce weight, but your parts are still too heavy and costly. This poor buy-to-fly ratio eats into your budget

WhatsApp us

We will contact you within 1 working day, please pay attention to the email with the suffix “jia@ksxinan.com”.