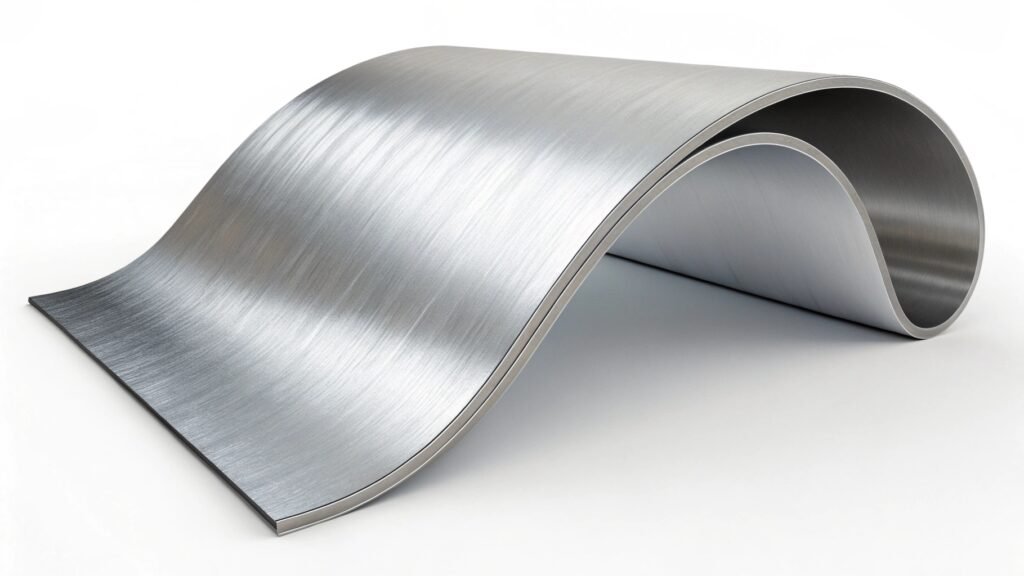

Are you wondering if aluminum sheets1 are flexible enough for your project's design needs? Understanding how easily aluminum can be manipulated is key to planning your fabrication.

Aluminum sheets can indeed be bent and shaped relatively easily, making them a versatile choice for many designs, but the ease depends on the alloy, temper, and the intended shape.

Let's explore how easily aluminum sheets can be formed and what factors influence this process.

Can aluminum be easily shaped?

Curious about aluminum's general formability? Knowing its inherent malleability is the first step to understanding its potential uses.

Aluminum is generally considered very easy to shape due to its low density and high ductility, allowing it to be formed into various complex geometries without fracturing.

Aluminum's reputation for being easy to shape stems from its fundamental material properties. It possesses a high ductility, meaning it can deform significantly under tensile stress without breaking. This property is crucial for forming processes like bending, stamping, and drawing. Furthermore, aluminum has a low melting point compared to steel, which makes it easier to work with in various manufacturing processes. Its low density also contributes to its ease of handling and shaping, as less force is required to manipulate it. Whether it's rolled into thin sheets, extruded into complex profiles, or cast into intricate shapes, aluminum readily conforms to desired forms. My experience with clients in the Middle East shows that its easy shapability is a major draw for custom projects, from decorative architectural elements to specialized industrial components. This inherent formability makes aluminum a preferred material where design flexibility is paramount.

Is aluminum resistant to bending?

Wondering if aluminum sheets will hold their shape or if they're prone to unwanted bending? Understanding their rigidity is important for structural integrity.

Aluminum, especially in its annealed or softer tempers, is not highly resistant to bending. It can be bent relatively easily, but harder tempers and thicker sheets offer greater resistance.

When we talk about aluminum's resistance to bending, it’s crucial to consider the specific alloy and temper of the aluminum sheet. Softer tempers, like the "O" temper (annealed), are very pliable and can be bent sharply with minimal force. This makes them ideal for applications requiring intricate folds or curves. However, as aluminum alloys are strengthened through heat treatment or work hardening (indicated by tempers like "H14," "H18," or "H32"), their resistance to bending increases significantly. A harder temper will require more force to bend and is less likely to deform accidentally. Thickness also plays a major role; thicker aluminum sheets naturally resist bending more than thinner ones. For structural applications where rigidity is important, engineers might specify thicker sheets or stronger alloys, or even consider processes like forging to increase the material's inherent strength and resistance to deformation. My clients often ask for specific bend radii, and we always advise them on the appropriate alloy and temper to achieve the desired outcome without cracking or excessive springback.

What thickness of aluminum is bendable?

Curious about the limits of aluminum sheet thickness when it comes to bending? Knowing this helps in planning fabrication projects.

Aluminum sheets can be bent across a wide range of thicknesses, from very thin foils to several millimeters or even more, but the minimum bend radius increases with thickness and alloy hardness.

The bendability of aluminum sheet is not strictly limited by a single thickness. You can bend aluminum that is incredibly thin, like foils used in packaging or electronics, to much thicker plates used in construction or vehicle bodies. However, as the thickness of the aluminum sheet increases, so does the minimum bend radius required to avoid cracking. For very thin sheets (e.g., 0.010 inches or 0.25 mm), sharp bends are often possible. As thickness increases to, say, 0.125 inches (3.175 mm) or 0.25 inches (6.35 mm), a larger radius is necessary. The alloy composition and temper are equally important. For instance, a softer alloy like 3003-H14 can be bent to a tighter radius than a harder alloy like 6061-T6 of the same thickness. When working with thicker aluminum, techniques like press braking with appropriate tooling are used, and the "springback" effect (where the material tries to return to its original shape after bending) also becomes more pronounced, requiring compensation. We always consider these factors when advising our clients on the best aluminum grades and bending specifications for their parts.

Can aluminum be curved?

Wondering if aluminum can achieve smooth, continuous curves, not just sharp bends? This is important for aesthetic and functional designs.

Yes, aluminum can be smoothly curved, often achieved through processes like rolling or specialized bending techniques that apply gradual pressure to create arcs and continuous curves.

Achieving a smooth, continuous curve in aluminum sheets is a common and important fabrication task. Unlike sharp bends, which involve a distinct change in direction at an angle, curving involves a gradual transition in shape. This is often accomplished using specialized machinery like roll bending machines or sweep bending dies in press brakes. Roll bending machines typically have three or four rollers that precisely control the curvature by applying pressure and feeding the sheet through them. The distance and pressure of the rollers determine the radius of the curve. Sweep bending, on the other hand, uses a die that gradually forms the curve as the sheet is pushed or pressed into it. The choice of method depends on the desired radius, the sheet thickness, and the alloy. Softer aluminum alloys and annealed tempers are generally easier to curve without experiencing strain lines or cracking. Aluminum's inherent malleability makes it well-suited for these processes, allowing for the creation of cylindrical shapes, curved panels, and other rounded architectural or industrial components.

Conclusion

Aluminum sheets are easily bent and curved due to their ductility, though harder tempers and greater thicknesses increase resistance; this formability is distinct from die-cutting and makes aluminum suitable for many shaping needs.

-

Explore the properties of aluminum sheets to understand their versatility in various design applications. ↩