Confused about the best forging method for your aluminum parts? Understanding the differences between open die and closed die forging is crucial for selecting the right process.

Open die forging offers greater flexibility and cost-effectiveness for large, custom, or simple parts, while closed die forging1 excels at producing complex, high-volume components with precision, each process having distinct advantages and limitations.

At SWA Forging, helping clients choose the right manufacturing process is a core part of what we do. When it comes to aluminum forgings, the decision between open die and closed die forging is fundamental. It impacts not only the final part's characteristics but also the cost and lead time.

What are the advantages of open die forging over closed die forging?

Open die forging provides a unique set of benefits that make it the preferred method for certain types of aluminum components.

Open die forging offers significant advantages in flexibility for shaping large or custom parts, lower tooling costs, and suitability for producing components with simpler geometries more economically, making it an excellent choice for prototypes and specialized orders.

Clients often ask why we might recommend open die forging2 for their specific needs. Its primary advantages lie in its adaptability, lower initial investment in tooling, and its capability to handle a wide range of sizes and simpler forms efficiently.

Here are the key advantages of open die forging:

- Greater Flexibility: The process uses simpler dies that don't fully enclose the workpiece. This allows for more manipulation of the metal, making it easier to create custom sizes and shapes for large parts like rings, discs, and shafts.

- Lower Tooling Costs: Unlike closed die forging, which requires complex, custom-made dies, open die forging uses simpler tooling. This significantly reduces the initial investment, making it more economical for smaller production runs or custom orders.

- Cost-Effectiveness for Large Parts: For very large or heavy components, the cost of creating intricate closed dies can be prohibitive. Open die forging allows for the gradual shaping of large metal masses without the need for massive, complex tooling.

- Material Integrity: Like all forging processes, open die forging refines the grain structure of the aluminum alloy. This creates a stronger, more durable part with improved toughness and fatigue resistance compared to casting or machining from bar stock.

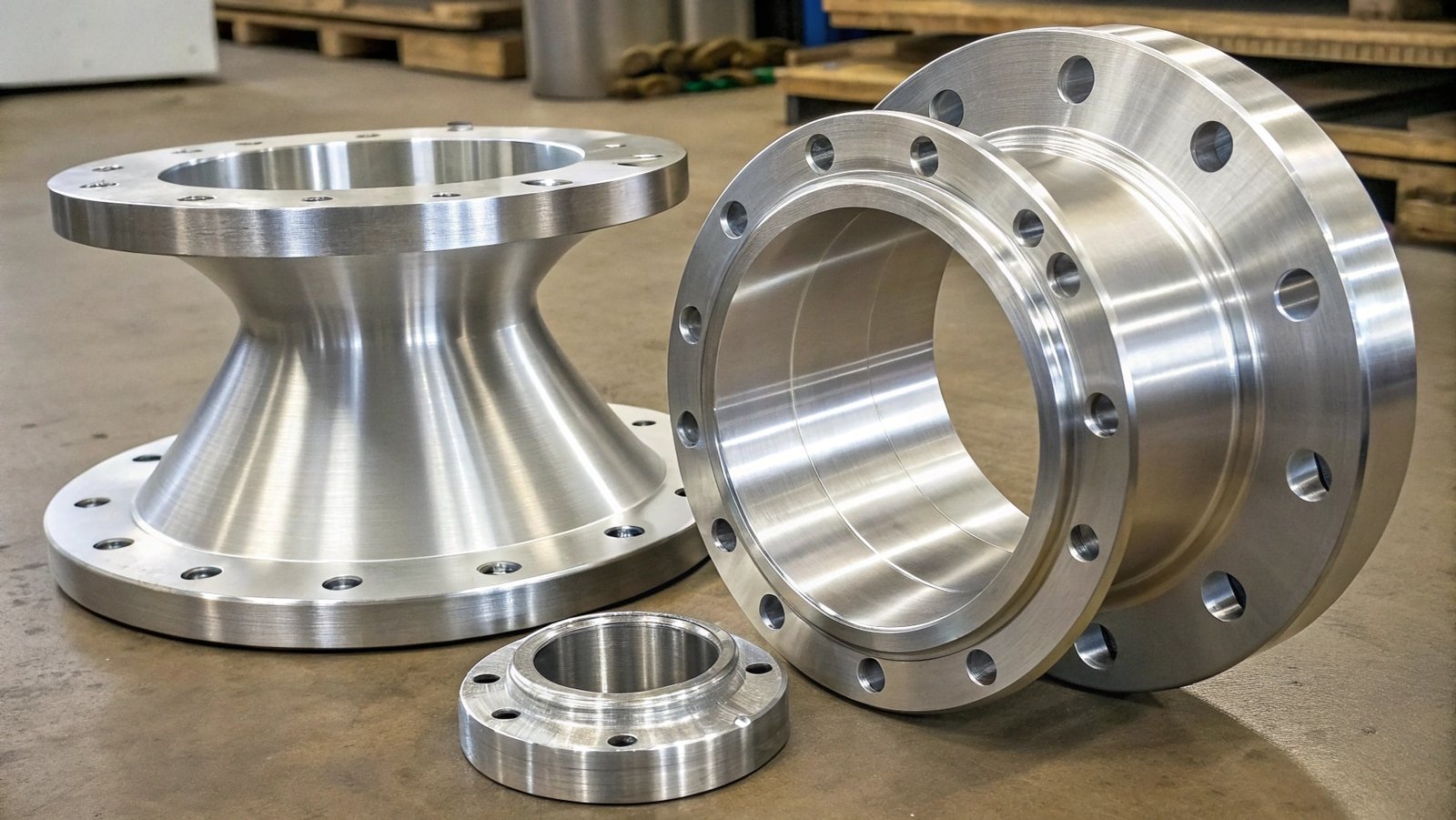

- Versatility in Part Types: It is well-suited for producing a variety of basic shapes including rings, discs, blocks, bars, and simple shafts, often with customized dimensions.

These benefits make open die forging a powerful option for many custom and large-scale aluminum component requirements.

What is closed die forging primarily used for?

Closed die forging is a precision-driven process, ideal for manufacturing parts that demand high accuracy and consistency in large volumes.

Closed die forging is primarily used for producing complex-shaped metal components in high volumes, ensuring tight dimensional tolerances and excellent surface finish. It’s essential for critical parts in industries like automotive, aerospace, and defense where precision and uniformity are paramount.

When discussing manufacturing techniques, it’s important to highlight where each process truly shines. Closed die forging is the method of choice when precision, repeatability, and intricate shapes are required for many identical parts, particularly in high-performance applications.

Here’s what closed die forging is primarily used for:

- Intricate and Complex Shapes: The impression in the dies precisely dictates the final shape, allowing for the creation of complex geometries with features like ribs, bosses, and undercuts that would be difficult or impossible with other methods.

- High-Volume Production: Once the initial investment in tooling is made, the closed die process is highly efficient for mass-producing identical parts with minimal variation from one piece to the next.

- Precision and Dimensional Accuracy: The enclosed nature of the die ensures that the material fills the cavity precisely, resulting in parts with very accurate dimensions and superior surface finishes, often reducing the need for extensive secondary machining.

- Enhanced Mechanical Properties: The forging process aligns the metal's grain structure with the part's contours, leading to superior strength, ductility, and fatigue resistance compared to other manufacturing methods like casting.

- Critical Applications: It's widely used for essential components in:

- Automotive: Connecting rods, crankshafts, gears, suspension components.

- Aerospace: Turbine blades, structural airframe parts, landing gear elements.

- Defense: Components for weaponry, vehicles, and aircraft systems.

The ability of closed die forging to produce complex, high-quality parts consistently in large numbers makes it a cornerstone of many advanced manufacturing sectors.

Which is stronger, forging or casting?

When comparing strength, forging generally produces stronger, more reliable metal parts than casting.

Forging is typically stronger than casting because the process refines the metal's grain structure and aligns it with the part's contours, eliminating internal voids and weaknesses. This results in superior tensile strength, yield strength, ductility, and fatigue resistance compared to cast parts, which can contain internal porosity and less uniform grain structures.

Clients often ask about the inherent strength advantages of forging. It’s a key differentiator that often drives the choice of manufacturing process, especially for critical components where material integrity is non-negotiable.

Here's why forging generally leads to stronger parts:

- Grain Structure Refinement: Forging involves plastic deformation of the metal. This process breaks down large, coarse grains into smaller, finer grains. These finer grains are more uniformly distributed and aligned along the lines of force, which significantly enhances the metal's strength, toughness, and ductility.

- Elimination of Defects: Casting involves pouring molten metal into a mold. This process can often lead to internal defects like porosity (tiny gas pockets), shrinkage cavities, and inclusions. These defects act as stress risers, weakening the part and making it more prone to failure under load. Forging, by deforming solid metal, essentially squeezes out these potential defects.

- Improved Fatigue Life: Because forged parts have a more uniform internal structure and are free from the stress-concentrating defects common in castings, they exhibit significantly better fatigue resistance. This means they can withstand repeated stress cycles for a longer duration before failing.

- Ductility and Toughness: The refined grain structure and absence of voids in forged parts also contribute to greater ductility (the ability to deform without fracturing) and toughness (the ability to absorb energy and resist fracture), especially at lower temperatures.

While casting offers design freedom for very complex shapes and can be more cost-effective for low-volume, intricate parts, forging consistently provides superior mechanical properties, making it the preferred method for high-stress and critical applications.

What are the limitations of closed die forging?

While closed die forging is highly precise, it comes with certain limitations that are important for clients to consider.

The main limitations of closed die forging include high upfront tooling costs, a longer lead time for die production, reduced flexibility for design modifications after die creation, and potential challenges in achieving extremely large or very simple bulk components cost-effectively compared to open die forging.

Understanding the drawbacks of any manufacturing process is crucial for making informed decisions. For closed die forging, the primary limitations often relate to the significant investment required for tooling and the process's inherent lack of flexibility once production begins.

Here are the key limitations of closed die forging:

- High Tooling Costs: The most significant barrier to entry for closed die forging is the expense associated with designing and manufacturing the precise, custom dies. These dies must withstand immense pressure and are complex to produce, making them a substantial initial investment.

- Longer Lead Times: The process of creating these specialized dies involves significant design, machining, and testing time. This means that the ramp-up to production can be considerably longer than with methods that require less complex tooling.

- Lack of Design Flexibility: Once the dies are created, they are fixed to a specific part geometry. If design changes are needed, new dies must be produced, which is costly and time-consuming. This makes it less suitable for rapid prototyping or applications with frequent design iterations.

- Size and Shape Constraints: While excellent for complex shapes, closed die forging can become impractical or excessively expensive for extremely large components or for parts with very simple, uniform geometries where open die forging might be more economical.

- Internal Feature Limitations: While external shapes are precisely formed, creating intricate internal features or deep cavities solely through closed die forging can be challenging and may still require subsequent machining operations.

These limitations highlight that closed die forging is best suited for scenarios where high-volume production of a specific, complex part design justifies the significant upfront investment in tooling and lead time.

Conclusion

Choosing between open die and closed die forging at SWA Forging depends on your project's needs. Open die offers flexibility for large or custom parts, while closed die provides precision for complex, high-volume components. Forging generally yields stronger parts than casting, but closed die has limitations like high tooling costs and less design flexibility.