Confused about which aluminum alloy to pick for your forging needs? Selecting the wrong material can lead to costly mistakes and subpar performance.

Choosing the right aluminum alloy1 for forging is crucial for achieving desired mechanical properties, durability, and cost-effectiveness. Key factors include the application’s requirements for strength, corrosion resistance, weldability, and formability.

I often find myself guiding clients through this decision-making process. It’s not just about picking a material; it’s about understanding how that material will perform in their specific application.

How to choose the right aluminium alloy?

When clients ask for advice on selecting an aluminum alloy, I emphasize understanding their project's core needs. This initial consultation is key to providing the best recommendation.

To choose the right aluminum alloy, thoroughly assess the intended application’s requirements. Consider factors like desired strength, operating temperature, corrosion resistance2, ease of fabrication, and cost. Consulting with material experts can also provide valuable guidance.

Selecting the correct aluminum alloy is a critical first step in any forging project. It directly influences the final product’s performance, longevity, and overall suitability for its intended purpose. As a supplier, my goal is to help clients navigate this choice efficiently, ensuring they get the most value and reliability from their components.

Here’s a breakdown of considerations that influence alloy selection:

- Mechanical Properties: What level of strength, hardness, and ductility is needed? For high-stress applications, alloys like 7075 are often preferred due to their exceptional strength. For more general use, 6061 might be sufficient.

- Corrosion Resistance: Will the component be exposed to harsh environments? Some alloys, like those in the 5xxx series, offer excellent resistance to seawater, making them suitable for marine applications.

- Workability and Machinability: How easily does the alloy need to be formed or machined after forging? Alloys like 6061 are known for their good machinability and weldability.

- Heat Treatment Response: Does the application require post-forging heat treatment to enhance properties? Many aluminum alloys can be strengthened through heat treatment, and the specific response varies by alloy.

- Cost: While performance is key, budget constraints are also a reality. We aim to balance the highest performance with the most cost-effective solution for our clients.

Understanding these aspects allows me to recommend alloys that align with both technical requirements and economic considerations, ensuring client satisfaction.

What is the best aluminum alloy for forging?

The question of the "best" aluminum alloy often comes up. It's a good question, but the answer is rarely a single alloy. It really depends on what you need the forged part to do.

There isn't a single "best" aluminum alloy for all forging applications. The ideal choice depends heavily on the specific requirements of the end-use, balancing factors like strength, corrosion resistance, machinability, and cost. Alloys like 6061 and 7075 are very popular due to their versatile properties.

When asked about the best aluminum alloy for forging, it’s important to understand that "best" is subjective and entirely application-dependent. What works brilliantly for one client's needs might be overkill or insufficient for another's. My experience has shown that common, high-performance alloys like 6061 and 7075 are frequently excellent choices, but the precise selection requires a deep dive into the project specifics.

Let’s explore why certain alloys are so popular and when they shine:

1. Aluminum Alloy 6061

- Description: 6061 is a precipitation-hardening aluminum alloy1. It contains magnesium and silicon as its main alloying elements. It's considered a medium to high-strength alloy.

- Key Properties: Good corrosion resistance, good weldability, and good machinability. It responds well to heat treatment.

- Why it's good for forging: It’s versatile and cost-effective. It can be forged into complex shapes and offers a good balance of strength and toughness. It’s a workhorse alloy for many industries.

- Typical Applications: Structural components, automotive parts, bicycle frames, marine applications, aircraft components (though higher strength alloys are often preferred for critical parts).

- My Insight: For many general-purpose forging needs, 6061 is an excellent starting point. It offers a reliable performance at a competitive price point, which is often appreciated by traders and manufacturers alike.

2. Aluminum Alloy 7075

- Description: 7075 is a high-strength aluminum alloy. Its primary alloying elements are zinc, magnesium, and copper. It’s one of the strongest aluminum alloys available.

- Key Properties: Extremely high strength, good fatigue strength, and moderate corrosion resistance (can be susceptible to stress corrosion cracking if not treated properly). It is not as easily welded or machined as 6061.

- Why it's good for forging: When absolute strength and light weight are paramount, 7075 is often the alloy of choice. It can withstand significant mechanical stress.

- Typical Applications: Critical aerospace components, high-performance sporting goods, military applications, structural parts in demanding environments.

- My Insight: For clients in the aerospace sector or those building high-performance equipment, 7075 is often specified. Its superior strength means lighter parts that can handle extreme loads. However, its higher cost and processing challenges mean it’s reserved for applications where its properties are truly essential.

Other Common Forging Alloys

- Aluminum Alloy 20243: Known for its high strength and good fatigue properties, often used in aerospace applications4. It contains copper as a primary alloying element.

- Aluminum Alloy 50835: Offers excellent corrosion resistance, particularly to seawater, and good weldability. It's often used in marine applications and cryogenic vessels.

The choice between these, or other specialized alloys, hinges entirely on the specific demands of the forged part. I always encourage clients to provide as much detail as possible about their application so we can make the most informed recommendation.

How to determine the alloy of aluminum?

Clients sometimes receive aluminum material and need to verify its alloy designation. It's a vital step, especially for quality-critical applications.

Determining the alloy of aluminum typically involves a combination of visual inspection, physical property testing, and more advanced methods like spectroscopy. Chemical analysis is the most definitive way to identify the specific alloy composition.

For any serious manufacturer or trader, knowing the exact alloy of the aluminum they are working with is non-negotiable. Mistakes in alloy identification can lead to catastrophic failures in finished products, especially in sensitive industries like aerospace or automotive. My team and I rely on rigorous methods to ensure alloy integrity from raw material intake to finished product shipment.

Here are the common methods used to identify aluminum alloys:

| Method | Description | When it's Used |

|---|---|---|

| Visual Inspection | Alloys can sometimes be distinguished by color, surface finish, or markings. However, this is often unreliable and not definitive for most alloys. For example, some higher copper content alloys might have a slightly reddish tinge. | As a very initial, often unreliable, first check. Not a primary method for accurate identification. |

| Spark Testing | Grinding a small sample of aluminum against a grinding wheel produces sparks. The color, length, and pattern of the sparks can indicate the presence of certain alloying elements. For instance, alloys with higher magnesium content might produce different spark patterns. | A quick, relatively simple method for differentiating broad categories of aluminum alloys, but not precise enough for specific alloy identification. Useful for initial sorting. |

| Hardness Testing | Measuring the hardness of the aluminum using methods like Rockwell or Brinell scales. Different alloys have different inherent hardness levels, which can be affected by heat treatment. | Can help narrow down possibilities, especially when comparing against known hardness ranges for various alloys. It's often used in conjunction with other tests. |

| Density Measurement | While all aluminum alloys are relatively light, slight variations in density can exist due to different alloying elements. Measuring the density of a sample can offer clues. | Less common as a primary method due to the subtle differences, but can be a supplementary data point in a battery of tests. |

| Spectroscopy (XRF/OES) | This is the most accurate and definitive method. X-Ray Fluorescence (XRF) or Optical Emission Spectrometry (OES) analyzes the elemental composition of the aluminum sample. This provides a precise breakdown of alloying elements and their percentages. | This is the standard for reliable alloy identification, especially for quality control, incoming material inspection, and verifying alloy specifications. It's essential for critical applications where alloy integrity is paramount. |

| Chemical Spot Testing | Using specific chemical solutions that react differently with various alloying elements to produce color changes. | Can be used for rapid field identification or as a supplementary test, but it requires careful handling and interpretation. |

At SWA Forging, we primarily rely on spectroscopy (XRF) for incoming material verification and final product certification. This ensures that what we forge is precisely what our clients require, giving them confidence in the quality and performance of our products, whether they are traders or direct users.

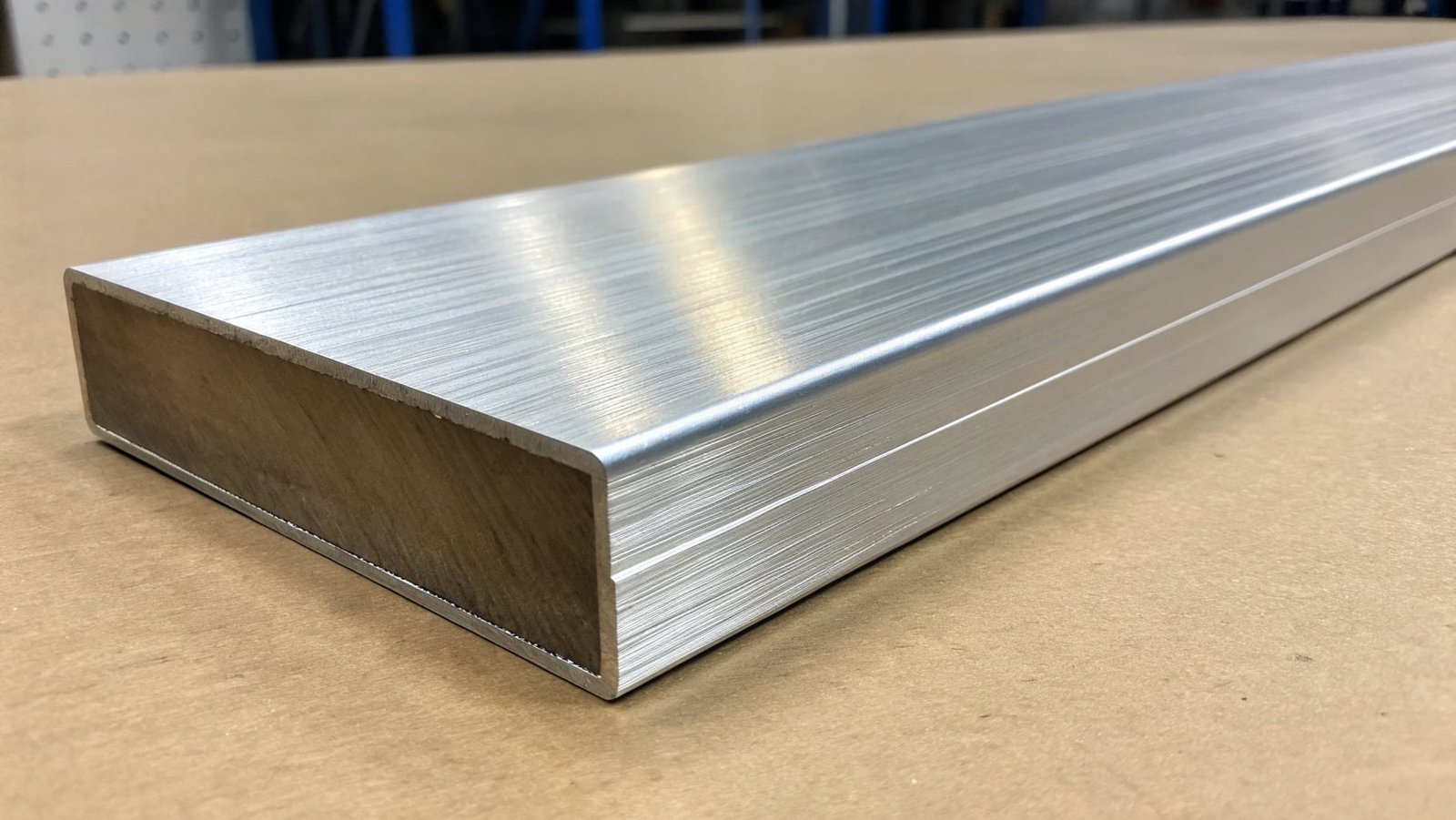

What is the Aluminium alloy for forging?

When clients ask about alloys specifically for forging, I typically highlight those that balance formability with the final mechanical properties needed after the process.

The most common aluminum alloys used for forging are in the 2xxx, 5xxx, 6xxx, and 7xxx series. Alloys like 6061, 7075, 2024, and 5083 are frequently selected due to their good forgeability and desirable mechanical properties after the forging process.

Understanding which aluminum alloys are best suited for forging is fundamental to our operation at SWA Forging. The inherent characteristics of an alloy dictate how it will behave under the high pressures and temperatures of the forging process, as well as its performance in the final application. We work with a range of alloys, each selected for its specific benefits in different forging scenarios.

Let’s look at the common series and their typical uses in forging:

- 1xxx Series (Pure Aluminum): While not typically used for high-strength forged components, the 1xxx series (e.g., 1100) is very formable and has excellent corrosion resistance. It’s sometimes used for simpler forged items where strength is not a primary concern.

- 2xxx Series (Aluminum-Copper Alloys): These alloys, such as 2014 and 2024, offer very high strength, especially after heat treatment. They are commonly used in aerospace applications where strength-to-weight ratio is critical. However, they have lower corrosion resistance and are not as easily welded as other series.

- 5xxx Series (Aluminum-Magnesium Alloys): Alloys like 5083 and 5086 are known for their excellent corrosion resistance, particularly in marine environments, and good weldability. They offer good strength and are often used for forged marine components, tanks, and structural parts that need to withstand corrosive conditions.

- 6xxx Series (Aluminum-Magnesium-Silicon Alloys): The most popular series for general forging is the 6xxx series, with 6061 being the prime example. This alloy provides a good combination of strength, corrosion resistance, weldability, and machinability. It’s very responsive to heat treatment, allowing for a wide range of mechanical properties. This versatility makes it ideal for countless applications across various industries.

- 7xxx Series (Aluminum-Zinc Alloys): This series, notably 7075 and 7050, offers the highest strength among aluminum alloys. They are preferred for highly stressed components in aerospace and high-performance equipment where maximum strength and fatigue resistance are essential. While they can be forged, they require careful control of process parameters due to their sensitivity to temperature and potential for cracking.

My role is to ensure that the chosen alloy meets all the technical specifications provided by our clients, whether they are traders needing material for distribution or machining companies requiring precise properties for their manufacturing processes.

Conclusion

Choosing the right aluminum alloy for forging depends on application needs. Alloys like 6061 and 7075 are popular, but identifying the alloy accurately is key to success.

-

Explore this link to understand the various aluminum alloys and their specific applications in forging. ↩ ↩

-

Discover how different aluminum alloys resist corrosion and which ones are best for harsh environments. ↩

-

Find out about Aluminum Alloy 2024 and its suitability for aerospace applications due to its high strength. ↩

-

Discover the aluminum alloys that meet the stringent requirements of the aerospace industry. ↩

-

Explore the advantages of Aluminum Alloy 5083, especially its corrosion resistance in marine environments. ↩