1. Material Composition & Manufacturing Process

5083 aluminum alloy (ASTM B209, EN AW-5083) is a high-strength, non-heat-treatable Al-Mg alloy renowned for exceptional weldability and superior corrosion resistance in marine environments. The ultra-thick forged plate variant offers enhanced mechanical properties through controlled deformation processing:

- Primary Alloying Elements:

- Magnesium (Mg): 4.0-4.9% (primary solid-solution strengthener)

- Manganese (Mn): 0.40-1.0% (grain structure refinement)

- Chromium (Cr): 0.05-0.25% (corrosion resistance enhancement)

- Titanium (Ti): 0.05-0.15% (grain refinement)

- Base Material:

- Aluminum (Al): ≥92.4% (balance)

- Controlled Impurities:

- Iron (Fe): ≤0.40% max

- Silicon (Si): ≤0.40% max

- Copper (Cu): ≤0.10% max

- Zinc (Zn): ≤0.25% max

Specialized Ultra-Thick Forging Process:

- Premium Ingot Production:

- Direct Chill (DC) semi-continuous casting

- Grain refinement with Ti-B additions

- Melt degassing to <0.1ml H₂/100g Al

- Filtration through ceramic foam filters

- Homogenization Treatment:

- 500-520°C for 24-36 hours

- Computer-controlled cooling rate

- Microstructural equilibration

- Surface Preparation:

- Scalping of segregation layer (minimum 10mm)

- Surface inspection for defects

- Preheating for Forging:

- Staged heating to 380-430°C

- Temperature uniformity ±5°C

- Multi-Directional Open-Die Forging:

- Initial forging temperature: 400-425°C

- Final forging temperature: 340-380°C

- Deformation ratio: 3:1 to 5:1

- Multi-directional working to optimize properties

- Specialized dies for ultra-thick sections

- Controlled Cooling:

- Programmed cooling rate to minimize residual stress

- Air-cooling with thermal blankets for thick sections

- Stress Relief Treatment:

- 240-300°C for 1 hour per 25mm thickness

- Furnace cooling to below 200°C

- Final Processing:

- Precision machining to customer specifications

- Surface inspection and cleaning

- Protective packaging for shipment

All manufacturing processes are performed under ISO 9001 quality management system with complete traceability.

2. Mechanical Properties of Ultra-Thick 5083 Forged Plate

| Property | Minimum | Typical | Test Standard | Ultra-Thick Advantage |

| Ultimate Tensile Strength | 290 MPa | 305-330 MPa | ASTM B557 | Uniform properties throughout section |

| Yield Strength (0.2%) | 145 MPa | 160-185 MPa | ASTM B557 | Enhanced through-thickness strength |

| Elongation (50mm gauge) | 12% | 16-22% | ASTM B557 | Superior ductility across full section |

| Hardness (Brinell) | 85 HB | 90-100 HB | ASTM E10 | Consistent hardness profile |

| Shear Strength | 175 MPa | 185-200 MPa | ASTM B769 | Enhanced joint reliability |

| Fatigue Strength (10⁸) | 120 MPa | 125-140 MPa | ASTM E466 | Improved cyclic loading performance |

| Compressive Yield | 145 MPa | 160-190 MPa | ASTM E9 | Critical for load-bearing applications |

| Bearing Strength (e/D=2.0) | 385 MPa | 400-430 MPa | ASTM E238 | Superior fastener performance |

| Impact Energy (Charpy) | 35 J | 40-50 J | ASTM E23 | Enhanced toughness at low temperatures |

Through-Thickness Performance:

- Property variation <5% between surface and core (up to 200mm thickness)

- Directionality ratio (L:LT:ST): 1.00:0.95:0.90 for tensile strength

- Core temperature maintained within critical processing window

- Hardness variation <8 HB from surface to center

3. Microstructural Control for Ultra-Thick Sections

Critical Forging Parameters:

- Strain Distribution Control:

- Minimum total true strain: 1.1-1.3

- Strain rate: 0.01-0.1 s⁻¹

- Multi-directional working (minimum 25% in secondary direction)

- Intermittent reheating for sections >150mm

- Temperature Management:

- Maximum temperature gradient: 30°C across section

- Computer-controlled thermal profile monitoring

- Extended dwell times for temperature homogenization

- Specialized handling equipment for minimal heat loss

Microstructural Characteristics:

- Grain Size: ASTM 5-7 (30-60μm)

- Grain Morphology: Partially recrystallized structure

- Al₆Mn dispersoid distribution: 0.1-0.5μm diameter

- Mg₂Si precipitate control: <0.5 volume percent

- Al-Fe-Mn intermetallic phases: Controlled morphology

- Recrystallized Volume Fraction: 40-60%

- Texture: Mixed deformation/recrystallization texture

- Grain Aspect Ratio: 1.5:1 maximum in final product

Special Features:

- Subgrain structure with high misorientation angles

- Limited recovery due to Mg solute drag effect

- Al₃Mg₂ precipitation controlled to prevent sensitization

- Enhanced dislocation density: 5-8×10¹⁰/cm²

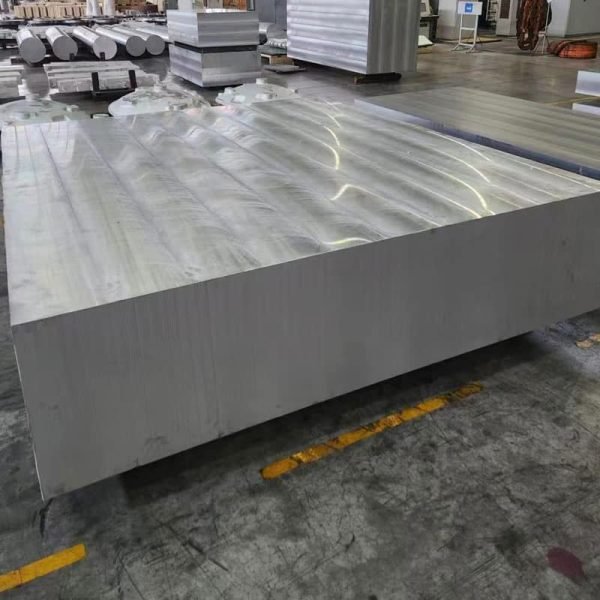

4. Dimensional Specifications & Tolerances

| Parameter | Standard Range | Precision Tolerance | Commercial Tolerance |

| Thickness | 150-400 mm | ±3 mm | ±5 mm |

| Width | 1000-3000 mm | ±5 mm | ±8 mm |

| Length | 2000-8000 mm | ±7 mm | ±12 mm |

| Flatness | N/A | 0.2% of length | 0.4% of length |

| Parallelism | N/A | 0.6% of thickness | 1.0% of thickness |

| Edge Straightness | N/A | 2 mm/m | 4 mm/m |

| Surface Roughness | N/A | 6.4 μm Ra max | 12.5 μm Ra max |

Ultra-Thick Specific Parameters:

- Density: 2.66 g/cm³ (±0.01)

- Weight Calculation: Thickness(mm) × Width(m) × Length(m) × 2.66 = Weight(kg)

- Maximum Single Plate Weight: 20,000 kg

- Machining Allowance: Recommend 15mm per side minimum for critical dimensions

- Stress Relief: Required before precision machining for plates >200mm

- Plate Flatness: Measured under self-weight on flat surface

- Ultrasonic Testing: 100% volumetric inspection available

5. Corrosion Resistance Performance

| Environment | Performance | Corrosion Rate | Expected Service Life |

| Marine Atmosphere | Excellent | <0.02 mm/year | 30+ years |

| Immersed Seawater | Very Good | <0.10 mm/year | 25+ years |

| Industrial Exposure | Excellent | <0.05 mm/year | 25+ years |

| Fresh Water | Excellent | Negligible | 40+ years |

| Stress Corrosion | Excellent | Highly resistant | Design life |

| Exfoliation | Excellent | EXCO rating EA | Design life |

| Galvanic Coupling | Fair | Isolation required | Application dependent |

Corrosion Protection Options:

- Anodizing:

- Type II (Sulfuric acid): 10-25μm thickness

- Type III (Hard anodize): 25-75μm thickness

- Marine-grade sealing treatments

- Conversion Coatings:

- Chromate conversion per MIL-DTL-5541

- Chrome-free alternatives for environmental compliance

- Titanium/Zirconium-based treatments

- Protective Systems:

- Epoxy primer + polyurethane topcoat

- Marine-grade multi-layer systems

- Sacrificial zinc-rich primers

- High-build epoxy coatings for immersion service

Environmental Performance Factors:

- Sensitization Resistance: Superior to 5086 alloy

- NAMLT Test Performance: <15mg/cm²

- IGC Resistance: Excellent after stabilization treatment

- H₂ Embrittlement: Minimal susceptibility

6. Machining & Fabrication Characteristics

| Operation | Tool Material | Recommended Parameters | Notes for Ultra-Thick Sections |

| Heavy Milling | Carbide | Vc=300-600 m/min, fz=0.15-0.30 mm | Climb milling recommended |

| Deep Hole Drilling | Carbide drills | Vc=60-100 m/min, fn=0.15-0.25 mm/rev | Step drilling for deep holes |

| Face Milling | PCD cutters | Vc=500-1000 m/min | High positive rake angles |

| Turning | Carbide/PCD | Vc=200-500 m/min | Rigid setup essential |

| Tapping | HSS-E taps | Vc=10-20 m/min | 50% thread recommended |

| Sawing | Carbide-tipped | 40-60 m/min | Flood coolant mandatory |

Fabrication Considerations:

- Forming Limits: Minimum bend radius 2.5× material thickness

- Cold Working: Limited to 15-20% before annealing

- Hot Working: 260-370°C optimal temperature range

- Weldability: Excellent with 5183, 5356, or 5556 filler

- Welding Methods: GMAW, GTAW, FCAW suitable

- Post-weld Treatment: Brush/needle scaling recommended

- Stress Relief After Welding: 200°C for 1 hour per 25mm

- Cutting Methods: Plasma, waterjet, or sawing preferred

7. Welding Performance & Recommendations

| Welding Process | Filler Material | Parameters | Special Considerations |

| GMAW (MIG) | ER5183, ER5556 | DCEP, 22-26V, 140-250A | Pulse spray transfer recommended |

| GTAW (TIG) | ER5183, ER5356 | AC, 12-15V, 120-200A | Thoriated tungsten electrodes |

| FCAW | E5183T, E5556T | DCEP, 24-28V, 150-260A | Minimal interpass cleaning |

| SAW | ER5183, ER5356 | 26-30V, 350-550A | Neutral or slightly basic flux |

Welding Best Practices for Ultra-Thick Sections:

- Joint Preparation:

- X-groove or double-V for thickness >25mm

- Root gap 2-4mm

- Root face 1-3mm

- Bevel angle 50-60°

- Thorough degreasing with acetone or MEK

- Preheating:

- Generally not required

- For sections >200mm, preheat 50-80°C to reduce thermal gradient

- Interpass Temperature:

- Maximum 120°C

- Monitor with infrared thermometer

- Post-weld Treatment:

- Stress relief recommended for thick sections

- Thorough cleaning of flux and spatter

- Inspection Methods:

- Visual inspection per AWS D1.2

- Radiographic or ultrasonic testing for critical joints

- Dye penetrant for surface defects

8. Physical Properties for Engineering Design

| Property | Value | Design Implications |

| Density | 2.66 g/cm³ | Weight calculations and buoyancy |

| Melting Range | 574-638°C | Welding and heat treatment parameters |

| Thermal Conductivity | 117 W/m·K | Heat dissipation in thermal applications |

| Electrical Conductivity | 29% IACS | Electrical applications and design |

| Specific Heat Capacity | 900 J/kg·K | Thermal inertia calculations |

| Thermal Expansion | 23.8 ×10⁻⁶/K | Expansion joint design and thermal stress |

| Young’s Modulus | 71 GPa | Structural stiffness and deflection |

| Poisson’s Ratio | 0.33 | Strain relationships in complex loading |

| Damping Capacity | Moderate (0.01-0.02) | Vibration control applications |

Environmental Performance:

- Operating Temperature Range: -196°C to +200°C

- Cryogenic Performance: Excellent toughness retention

- Fire Resistance: Non-combustible

- Magnetic Properties: Non-magnetic

- Radiation Resistance: Excellent

- Recyclability: 100% recyclable with no quality loss

- Environmental Impact: Lower energy footprint than steel

9. Quality Assurance & Testing Protocol

Standard Inspection Regime:

- Chemical Composition Testing:

- Optical emission spectroscopy

- Verification of all alloying elements

- Mechanical Testing:

- Tensile testing (longitudinal and transverse directions)

- Hardness mapping (surface and cross-section)

- Impact testing for critical applications

- Non-Destructive Testing:

- Ultrasonic inspection per ASTM A578/A578M

- Dye penetrant inspection for surface defects

- Dimensional Inspection:

- CMM verification of critical dimensions

- Thickness mapping at specified grid points

- Flatness measurement under self-weight

- Microstructural Analysis:

- Grain size determination

- Inclusion rating per ASTM E45

- Sensitization testing for H tempers

- Metallographic examination

Certification Options:

- Mill Test Report (EN 10204 3.1)

- Third-party inspection certification (EN 10204 3.2)

- DNV-GL certification for marine applications

- ABS certification for marine structures

- Lloyd’s Register certification

- Customer-specific certification requirements

- Material traceability documentation

- Production record documentation

10. Industrial Applications & Use Cases

Primary Applications:

- Naval and commercial shipbuilding

- Offshore oil & gas platforms

- Pressure vessel components

- Cryogenic storage and transport

- Heavy transportation structures

- Bridge decking and structural components

- Defense industry applications

- Chemical processing equipment

- Mining equipment structures

- Marine propulsion system components

Specific Use Cases:

- LNG Carrier Structural Components:

- Superior low-temperature toughness

- Excellent weldability for complex structures

- Good strength-to-weight ratio