Tired of components that fail under pressure? Discover how SWA Forging’s custom aluminum forgings1 offer unparalleled strength and reliability.

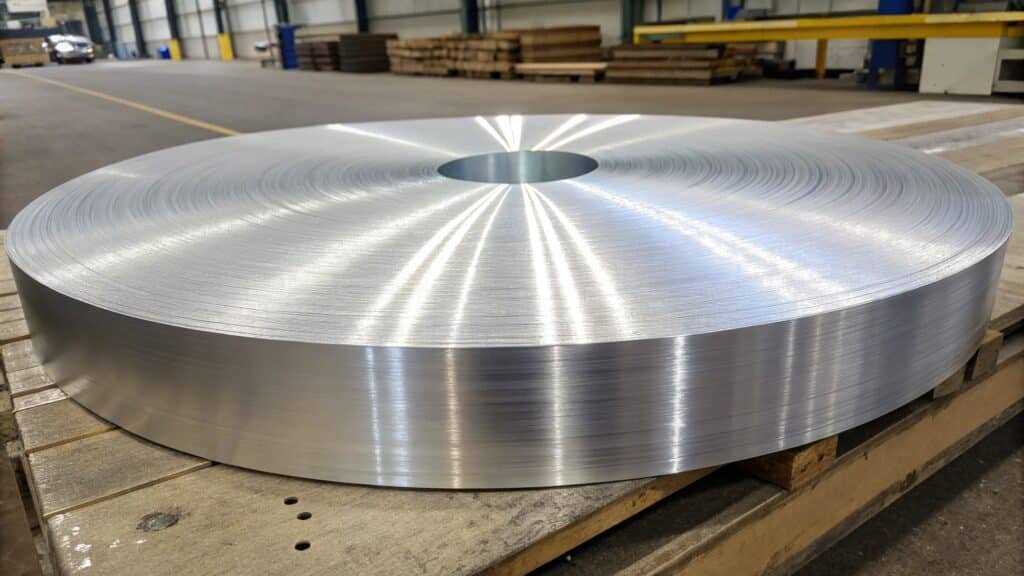

SWA Forging’s custom aluminum forged rings and discs provide superior mechanical properties, enhanced durability, and greater precision compared to standard aluminum tubing, making them ideal for high-stress applications in aerospace, automotive, and industrial sectors.

Many clients come to us because standard aluminum parts, like tubing, are not meeting their performance requirements. They need components that can withstand higher loads, resist fatigue, and maintain their integrity in challenging conditions. At SWA Forging, we specialize in providing these high-performance solutions through the art and science of aluminum forging. Our process is designed to deliver components that simply perform better.

What are the advantages of aluminium forging?

Aluminum forging offers significant advantages over other manufacturing methods, especially when high strength and durability are critical.

The advantages of aluminum forging include superior mechanical properties such as higher strength, improved toughness, and excellent fatigue resistance due to a refined grain structure. Forged parts also exhibit better ductility, dimensional accuracy, and consistency, making them ideal for demanding applications where reliability is paramount.

When we at SWA Forging discuss our capabilities, the advantages of the forging process itself are central to what we offer. It’s not just about shaping metal; it’s about fundamentally improving its inherent properties. This enhanced performance is why our custom-forged rings and discs are chosen for critical applications where failure is not an option, often outperforming even high-quality machined parts or standard tubing.

Here are the key advantages of aluminum forging:

- Enhanced Mechanical Properties: Forging refines the grain structure of the aluminum alloy2. The grains are deformed and flowed in a direction that conforms to the shape of the part. This results in higher tensile strength, yield strength, and impact toughness compared to cast or machined parts.

- Improved Fatigue Strength: The refined and directional grain flow in forged components makes them much more resistant to fatigue failure. This is crucial for parts subjected to cyclic loading, such as in automotive engines or aircraft structures.

- Greater Ductility and Toughness: Forging produces parts that are more ductile and tougher. This means they can deform more before fracturing, providing an added margin of safety and reliability.

- Dimensional Accuracy and Consistency: While casting can achieve complex shapes, forging often offers better dimensional accuracy and tighter tolerances, especially after minimal machining. The process also yields more consistent results from part to part.

- Reduced Machining: Many forged parts can be manufactured closer to their final dimensions, requiring less subsequent machining. This can save time and material costs.

- Reliability in High-Stress Applications: Due to their superior strength and integrity, forged components are the preferred choice for critical applications where failure could have severe consequences.

These advantages are why we focus on forging for our specialized aluminum components.

What is the best aluminium for forging?

The "best" aluminum alloy for forging depends entirely on the specific application’s requirements, such as strength, corrosion resistance, weldability, and cost.

The best aluminum alloy for forging depends on the application’s needs, but common high-performance alloys like 6061 and 7075 are excellent choices, offering a balance of strength, corrosion resistance, and formability, while alloys like 1100 or 3003 offer good formability and corrosion resistance at lower strengths.

!

When we discuss forging at SWA Forging, selecting the right alloy is a critical first step. Different alloys behave differently under heat and pressure, and each has unique properties that make it suitable for specific end uses. Our team works closely with clients to identify the alloy that best meets their performance requirements, whether it’s for a large forged ring for industrial machinery or a precision-forged disc for aerospace.

Here are some of the top aluminum alloys for forging and their typical uses:

- 6061: This is one of the most popular and versatile aluminum alloys. It offers a good combination of strength, corrosion resistance, weldability, and machinability. It’s widely used for structural components, aerospace parts, automotive applications, and general-purpose forgings. It can be heat-treated to achieve higher strength levels.

- 7075: Known for its exceptional strength, often comparable to some steels, 7075 is a high-strength alloy. It’s primarily used in aerospace, military applications, and high-performance sporting goods where maximum strength-to-weight ratio is essential. However, it has lower corrosion resistance and weldability compared to 6061.

- 2000 Series (e.g., 2014, 2024): These alloys, containing copper as the primary alloying element, offer very high strength and good machinability, making them suitable for aerospace structural components. They have lower corrosion resistance and are more challenging to weld.

- 5000 Series (e.g., 5083, 5086): These alloys, with magnesium as the main alloying element, offer excellent corrosion resistance, good weldability, and moderate strength. They are often used in marine applications, automotive body panels, and where resistance to saltwater is crucial.

- 1000 Series (e.g., 1100): These are commercially pure aluminum alloys. They offer excellent corrosion resistance, formability, and weldability but have low mechanical strength. They are suitable for applications where strength is not a primary concern, like heat exchangers or decorative items.

The choice of alloy directly impacts the forging process and the final product’s performance.

Is forged aluminum stronger?

Yes, forged aluminum3 is generally stronger than aluminum formed by other methods like casting or machining from solid stock.

Forged aluminum is stronger than cast or machined aluminum due to its refined grain structure and the directional flow of grains created during the forging process. This structural integrity allows it to withstand higher stresses, resist fatigue, and offer superior toughness and ductility, making it the preferred choice for critical components.

The question of whether forged aluminum is stronger is a fundamental one that underscores why we choose forging at SWA Forging. The process itself imparts inherent strength that other methods cannot replicate. This is particularly relevant when comparing forged components to standard aluminum tubing or parts that might be cast or machined from bar stock.

Here’s why forged aluminum is stronger:

- Grain Structure Refinement: During forging, the aluminum alloy is heated and then shaped under pressure. This process refines the grain structure, making the grains smaller and more uniform. Smaller grains provide more grain boundaries, which act as barriers to dislocation movement, thus increasing strength and hardness.

- Grain Flow: Unlike casting, where grains can solidify randomly, forging causes the metal’s grain structure to flow and align with the contours of the part. This directional grain flow means that the material’s strength is optimized along the directions of expected stress, leading to superior performance in critical areas.

- Reduced Porosity and Inclusions: Casting can sometimes trap air bubbles (porosity) or impurities. Machining starts with a block that might have these issues. Forging, on the other hand, tends to distribute or eliminate internal defects through the applied pressure, resulting in a more homogeneous and defect-free material.

- Work Hardening (in some cases): Depending on the specific forging process and subsequent treatments, work hardening can further increase the strength of the aluminum.

This inherent strength advantage makes forged components ideal for high-stress environments where reliability is paramount, such as in our custom-made rings and discs.

Which type of aluminum is the strongest?

The strongest types of aluminum are typically found in the 7xxx series alloys, which are primarily alloyed with zinc.

The strongest types of aluminum are the 7xxx series alloys, such as 7075 and 7050. These alloys, when properly heat-treated (e.g., to T6 or T7351 tempers), can achieve tensile strengths comparable to many steels, offering an exceptional strength-to-weight ratio crucial for demanding applications like aerospace structures.

When clients require the utmost in material performance, we often look to the high-strength alloys. Understanding which aluminum alloy offers the highest mechanical properties is key to selecting the right material for our specialized forged components. At SWA Forging, we work with these advanced alloys to meet the most stringent requirements.

Here’s a breakdown of the strongest aluminum alloy series:

- 7xxx Series (Aluminum-Zinc Alloys): This series is renowned for its exceptionally high strength. Alloys like 7075, 7050, and 7068 are among the strongest aluminum alloys available. They are used in applications where maximum strength and lightness are critical, such as aircraft structural components, high-performance sporting equipment, and military applications. Their strength is significantly enhanced by heat treatment.

- 2xxx Series (Aluminum-Copper Alloys): These alloys, like 2024 and 2014, also offer high strength, particularly after heat treatment. They are commonly used in aerospace applications due to their good fatigue resistance and strength. However, they tend to have lower corrosion resistance compared to other series.

- 6xxx Series (Aluminum-Magnesium-Silicon Alloys): Alloys like 6061 and 6063 are very popular for their good balance of properties, including moderate strength, excellent corrosion resistance, and good formability. While not as strong as the 7xxx or 2xxx series, 6061 in its T6 temper provides significant strength for many structural applications.

For applications where ultimate strength is the primary concern, the 7xxx series alloys are generally the strongest available aluminum options.

Conclusion

At SWA Forging, we harness the advantages of aluminum forging to create components that offer superior strength, durability, and performance. By understanding the benefits of forging, selecting the best aluminum alloys for your needs, and recognizing the inherent strength of forged parts, you can ensure your components are engineered for success, even in the most demanding applications.

-

Explore how custom aluminum forgings can enhance strength and reliability in various applications. ↩

-

Explore the different aluminum alloys and their suitability for various forging applications. ↩

-

Understand the advantages of forged aluminum over cast aluminum in terms of strength and performance. ↩