Are you struggling to achieve the high-quality surface finishes your precision components demand from aluminum? The answer might lie in the starting material.

At SWA Forging, our specialized forging process inherently improves the material quality of aluminum, leading to significantly superior surface finishes and overall part quality during machining.

Let's explore how our forged aluminum1 can elevate your machined part quality.

What can be done to improve the machining of aluminum and its alloys?

Wondering how to get better results when machining aluminum2? Optimizing the process involves several key strategies.

To improve aluminum machining, select the right alloy and temper, use sharp tools with proper geometry, optimize cutting parameters (speed, feed, depth of cut), ensure effective chip evacuation, and utilize appropriate coolants.

Improving the machining of aluminum and its alloys involves a holistic approach, starting with the material itself and extending to the tools and process parameters. Firstly, selecting an aluminum alloy and temper known for good machinability is crucial; for instance, 6061-T63 (which we forge) is an excellent choice. Secondly, tooling is paramount: using very sharp tools made from high-speed steel (HSS) or carbide, specifically designed for aluminum (with polished flutes and high rake angles), will prevent material buildup and ensure clean cuts. Thirdly, optimizing cutting parameters is vital: using higher cutting speeds, moderate feed rates, and appropriate depths of cut can reduce heat and improve chip formation. Fourthly, effective chip evacuation is essential to prevent re-cutting and surface scratches; this can be achieved with through-spindle coolant or air blasts. Finally, using a suitable cutting fluid (coolant) not only cools the tool and workpiece but also helps lubricate the cut and flush chips away, leading to better surface finishes and extended tool life. My experience shows that combining these elements, especially starting with a superior forged material, makes a significant difference in achieving precision and quality.

What are the advantages of forged aluminum over cast aluminum?

If you're weighing the options between forged and cast aluminum, understanding their fundamental differences is crucial for optimal material selection.

Forged aluminum offers superior strength, better ductility, improved fatigue resistance, and a more consistent, defect-free internal structure compared to cast aluminum.

The distinction between forged and cast aluminum is significant, particularly concerning the final mechanical properties and machinability. The primary advantage of forged aluminum lies in its enhanced mechanical strength and integrity. During the forging process, the metal is subjected to immense pressure, which refines and aligns its internal grain structure. This grain flow follows the contour of the part, eliminating internal voids, porosity, and shrinkage defects that are common in cast materials. This results in significantly higher tensile strength, yield strength, and fatigue resistance for forged components. They can withstand greater loads, endure repeated stress cycles without failure, and are less prone to sudden fracturing. Furthermore, forged aluminum typically exhibits better ductility, meaning it can deform more plastically before breaking, which is crucial for impact resistance and reliability. While casting allows for more intricate shapes and can be more cost-effective for complex designs, the inherent structural integrity and performance of forged aluminum make it the preferred choice for critical, high-stress applications where reliability and durability are paramount. For my clients, especially those in industries like automotive and aerospace, these advantages translate directly into safer, more durable, and higher-performing end products.

What is the difference between forged and machined aluminum?

Confused about "forged" versus "machined" aluminum? Understanding their roles helps clarify the manufacturing process.

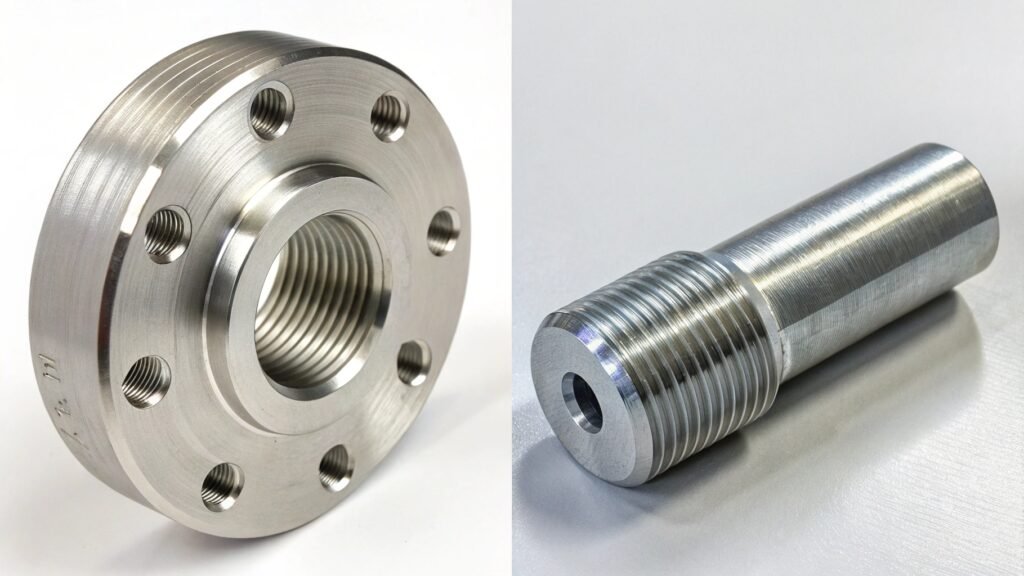

Forged aluminum refers to the process of shaping solid metal through localized compressive forces, creating a strong, refined material, while machined aluminum refers to removing material from a raw form (which can be forged or cast) using cutting tools to achieve a final shape.

It's important to understand that "forged" and "machined" describe different stages or aspects of aluminum manufacturing. Forging is a primary shaping process where a solid billet of aluminum is heated and then physically deformed under immense pressure from hammers or presses. This process rearranges the internal grain structure of the metal, making it stronger, tougher, and more ductile. The result is a "forging blank" or a "near-net shape" component that has superior mechanical properties compared to cast parts. On the other hand, machining is a secondary shaping process. It involves removing material from a workpiece (which could be a forged blank, a cast part, or an extruded bar) using cutting tools on machines like lathes, mills, or CNC centers. The goal of machining is to achieve precise dimensions, intricate features, and a desired surface finish. In many high-performance applications, a part will first be forged to gain its superior strength and internal integrity, and then it will be machined to achieve its final, precise dimensions and surface quality. Our expertise at SWA Forging lies in providing these high-quality forged blanks, which our machining clients then transform into their final products, benefiting from the superior starting material.

What is the most machinable aluminum alloy?

Looking for an aluminum alloy that cuts smoothly and efficiently? Identifying the best option can significantly impact your machining operations.

While various aluminum alloys offer good machinability, alloys like 2011, 6061, and 7075 are generally considered among the most machinable, offering good chip control and surface finish.

When selecting an aluminum alloy specifically for ease of machining, several options stand out, each with its own balance of properties. Alloy 2011 is often dubbed the "free-machining" aluminum alloy. It contains lead and bismuth, which act as chip breakers, leading to very short, brittle chips that clear easily, and allowing for high machining speeds. However, 2011 has lower corrosion resistance and strength compared to other common alloys. Alloy 6061, especially in its T6 temper (which is achieved after forging and heat treatment), is widely regarded for its excellent balance of strength, corrosion resistance, and good machinability. It produces relatively short chips and takes a good surface finish, making it a popular choice for general-purpose structural components that will be machined. Alloy 7075, particularly in its T6 or T7 temper, is a very strong aerospace-grade alloy that also offers good machinability, though it can be tougher on tools due to its hardness. For most of our clients, particularly those requiring strong yet easily machined components, the forged 6061-T6 alloy we provide offers an ideal combination of strength, consistency, and superior machinability, allowing them to achieve the high-quality finishes and tight tolerances their products demand.

Conclusion

Our forged aluminum enhances machinability by improving material structure, offering superior strength and consistency over cast aluminum, and differs from machining which is a material removal process. Forged 6061-T6 is an excellent choice for machinability.

-

Explore the advantages of forged aluminum, including strength and durability, which can enhance your manufacturing processes. ↩

-

Discover effective strategies to optimize your aluminum machining for better results and surface finishes. ↩

-

Learn why 6061-T6 is favored for its excellent machinability and strength in various applications. ↩