Your car's wheels face tough conditions. Weak wheels can be a big risk on the road. Strong, reliable forged wheels offer peace of mind and better performance.

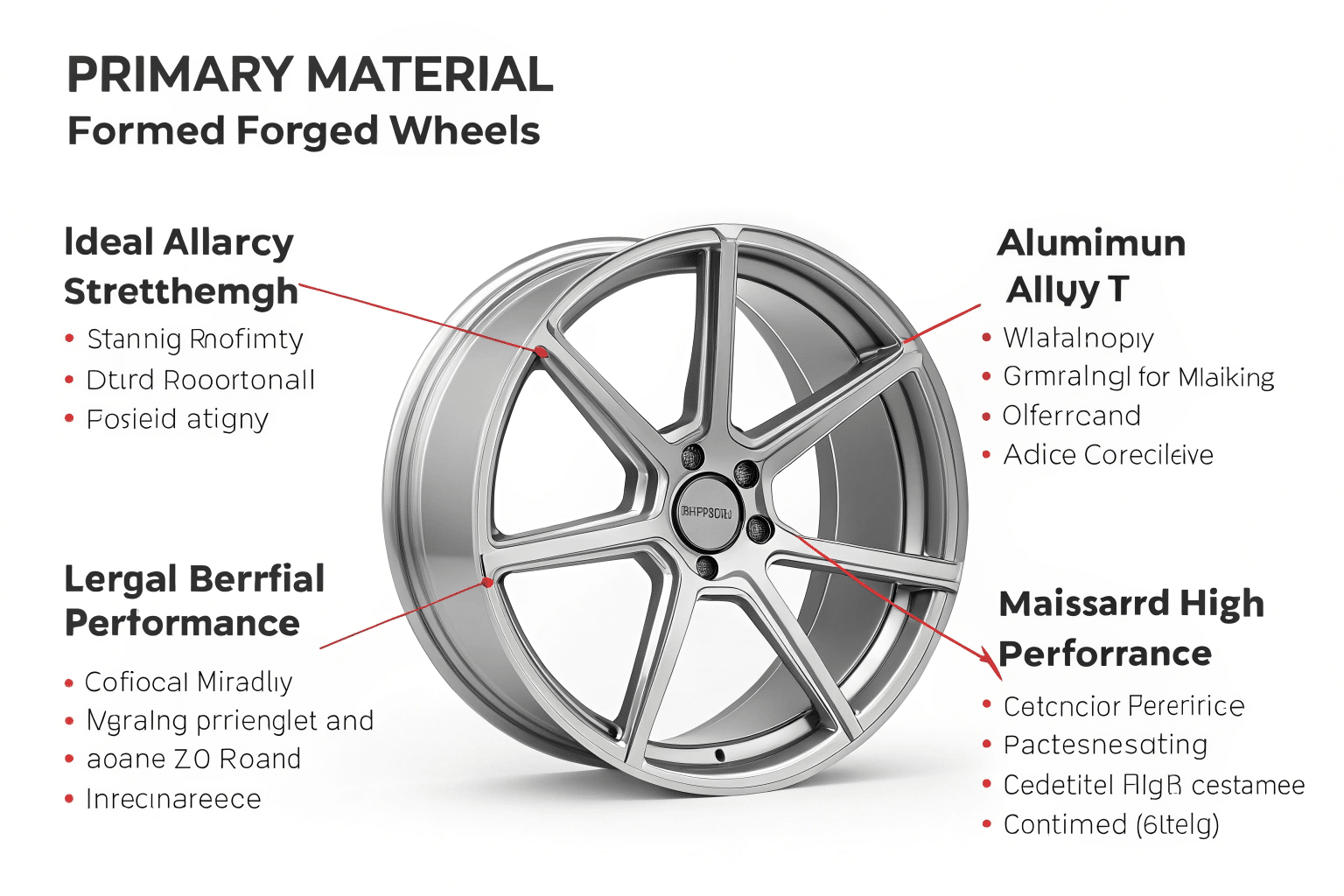

Forged wheels are typically made from high-strength aluminum alloys. The most common material is 6061-T6 aluminum, valued for its excellent combination of strength, lightness, and durability, often starting as a forged aluminum disc.

Understanding what goes into your wheels can help you appreciate their performance and safety. Many people ask about the materials and processes. We want to explore this further so you can make informed choices. Let's look deeper into the world of forged wheels.

What material is used for forged wheels?

Choosing the right material for wheels is very important. The wrong choice can affect performance and safety. Special aluminum alloys are selected for their unique properties.

The primary material for forged wheels is aluminum alloy, most notably 6061-T6. This specific alloy provides an ideal balance of strength, low weight, and corrosion resistance, making it perfect for high-performance and durable wheels.

At SWA Forging, we have a lot of experience with aluminum alloys. The 6061 aluminum alloy1 is a popular choice for forged wheels for several good reasons. First, it has a great strength-to-weight ratio. This means wheels can be strong without being too heavy. Lighter wheels improve a car's handling, acceleration, and fuel efficiency. The "T6" part refers to the tempering process. This heat treatment significantly increases the alloy's strength.

Another key benefit of 6061-T6 is its excellent corrosion resistance2. This is important because wheels are exposed to all sorts of weather and road conditions. Good corrosion resistance means the wheels will last longer and maintain their appearance.

The alloy is also very good for machining. After the initial forging process, the wheel blank needs to be precisely machined into its final shape. 6061-T6 allows for intricate designs and tight tolerances. We supply many forged aluminum discs in 6061-T6 specifically for customers who then machine them into high-quality wheels. While other alloys like some in the 7xxx series offer even higher strength, they might compromise on other aspects like corrosion resistance or cost, making 6061-T6 the balanced champion for most forged wheel applications.

How are fully forged wheels made?

The manufacturing process greatly impacts a wheel's quality. A poor process can result in weak, unreliable wheels. The forging process is designed to create superior strength and durability.

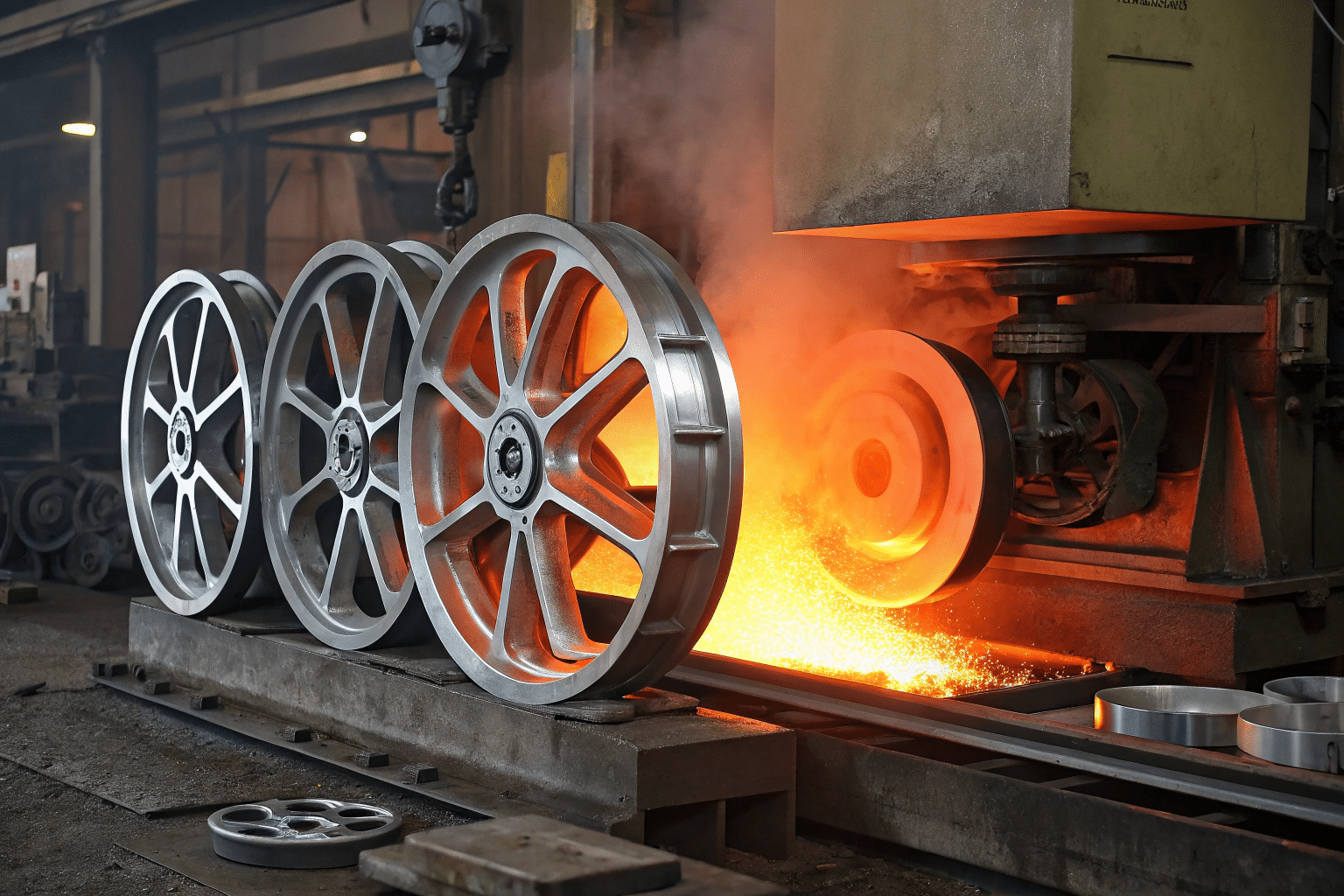

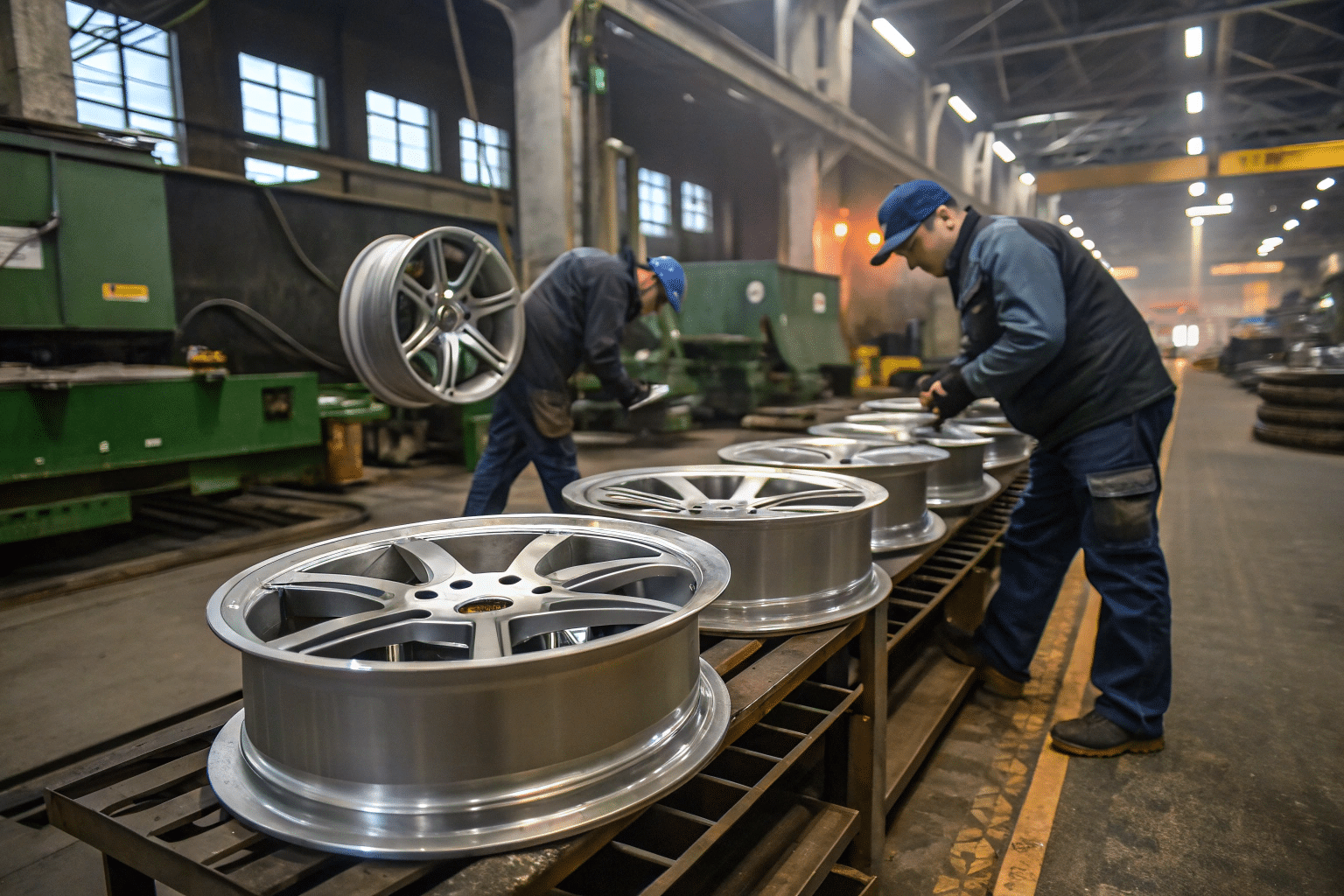

Fully forged wheels are made by taking a solid piece of aluminum alloy, heating it, and then shaping it under extreme pressure using powerful presses and dies. This process aligns the metal's grain structure, making it incredibly strong and dense.

The journey of a fully forged wheel is quite fascinating. It starts with a solid block, or billet, of high-grade aluminum alloy, often the 6061-T6 we discussed. At SWA Forging, we produce the initial forged discs that serve as this starting point for many wheel manufacturers. This billet is first heated to a specific temperature. This makes the aluminum malleable but not molten.

Then, the heated billet goes through a multi-stage forging process. It's subjected to immense pressure, often thousands of tons, from a hydraulic press. This pressure forces the aluminum into a series of dies that gradually shape it into a wheel blank. This process is not just about shape; it refines the metal's internal grain structure. The grains become elongated and aligned, eliminating porosity and voids. This results in a very dense and strong material.

After forging, the wheel blank undergoes heat treatment, the "T6" temper, to achieve its maximum strength and hardness. Once cooled and hardened, the forged blank is then precisely machined using CNC (Computer Numerical Control) machines. This step creates the final intricate design of the wheel, including the spokes, bolt holes, and hub bore. Finally, the wheel is finished with treatments like polishing, painting, or powder coating for appearance and extra protection. This meticulous process ensures each forged wheel is exceptionally strong, light, and reliable.

What is a forged rim?

The strength of a wheel's rim is critical for safety. A weak rim can bend or crack under stress. Forged rims are engineered to provide superior reliability and performance.

A forged rim is the outer part of the wheel that holds the tire. When it's "forged," it means this section has been manufactured using the forging process, resulting in a component that is significantly stronger and lighter than a cast rim.

When we talk about a "forged rim," we are focusing on a key part of the wheel assembly. The rim is the circular outer edge of the wheel where the tire is mounted. Its integrity is vital for the overall performance and safety of the wheel. If a wheel is described as having a forged rim, it means this specific component has undergone the intense pressure and shaping of the forging process.

This is a significant distinction from, say, cast rims. Cast rims are made by pouring molten aluminum into a mold. While this is a less expensive process, casting can sometimes result in a less dense material with potential for microscopic porosities, which can be points of weakness. Forged rims, due to the compressed and aligned grain structure, are much denser and stronger. This means a forged rim can be made lighter than a cast rim while still offering superior strength and impact resistance. This is why you often hear about the excellent strength-to-weight ratio of forged wheels. Furthermore, the denser material of a forged rim can also help with better heat dissipation, which is beneficial for brake performance. When a manufacturer states a wheel is "fully forged," it means the entire structure, including the rim and the center disc (spokes), is made through this superior process using materials like the 6061-T6 aluminum discs we supply.

What are the disadvantages of forged wheels?

Are there any downsides to choosing forged wheels? Most products have some trade-offs to consider. Understanding these helps you make a balanced decision based on your needs.

The main disadvantage of forged wheels is their higher cost compared to cast or flow-formed wheels. The complex manufacturing process, specialized equipment, and higher material quality contribute to this increased price point.

While forged wheels3 offer many benefits, there are a few considerations that might be seen as disadvantages for some buyers. The most significant one is cost. Producing a forged wheel is a more complex, time-consuming, and energy-intensive process compared to casting. The machinery involved, like massive hydraulic presses and precision dies, represents a huge investment. The raw material, typically high-grade aluminum alloy4 like 6061-T6, is also more expensive. All these factors contribute to a higher purchase price for forged wheels.

Another point can be design flexibility5. While modern forging techniques can create very attractive and intricate designs, the casting process generally allows for more complex and elaborate shapes more easily and at a lower cost. Forging prioritizes strength and material integrity, which can sometimes place some limitations on extremely ornate styling compared to what casting can achieve.

Finally, if a forged wheel does get severely damaged, repairing it can sometimes be more difficult or costly than repairing a cast wheel, though it's important to note that forged wheels are much less likely to damage in the first place due to their superior strength and ductility. For many users, especially in performance driving or heavy-duty applications, the significant advantages in strength, weight, and durability easily justify the higher initial investment.

Conclusion

Forged wheels, mainly crafted from 6061-T6 aluminum, provide top-tier strength and lightness. Though pricier, their performance and durability often make them a worthwhile investment for discerning users.

-

Explore the advantages of 6061 aluminum alloy, especially for forged wheels, to understand its strength and performance benefits. ↩

-

Learn how corrosion resistance impacts the durability and appearance of aluminum wheels, ensuring they last longer in various conditions. ↩

-

Explore this link to understand the pros and cons of forged wheels, helping you make an informed decision for your vehicle. ↩

-

Learn about high-grade aluminum alloys and their advantages in various applications, including automotive manufacturing. ↩

-

Discover the differences in design flexibility between forged and cast wheels to choose the best option for your style and needs. ↩