Deep wells are tough environments. Traditional pipes can corrode or fail under extreme pressure. This demands innovative materials for reliable and safe energy extraction.

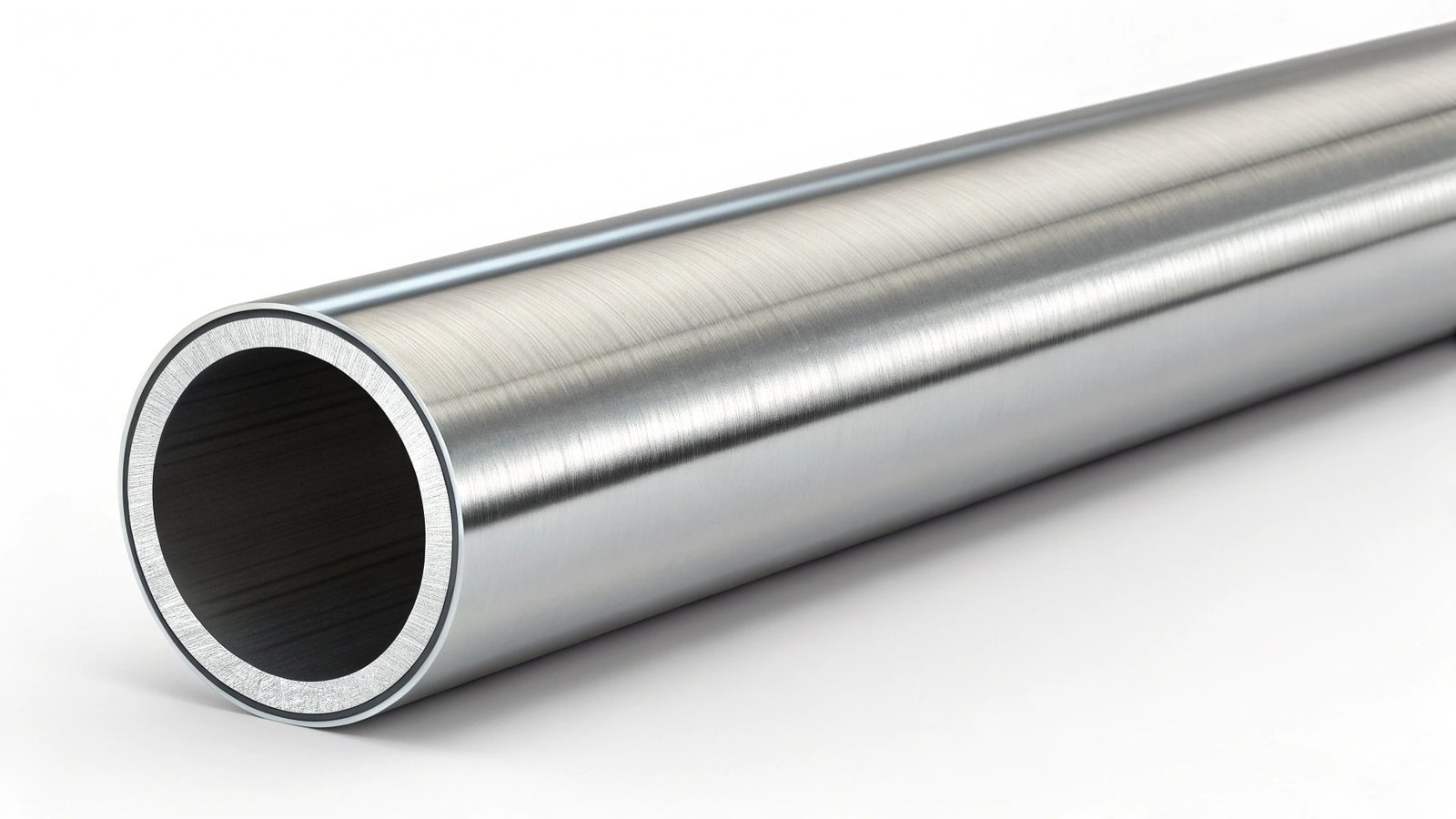

Petroleum deep well exploration primarily uses steel drill pipes, casing, and production tubing. However, 6061-T6 aluminum seamless tubes are gaining popularity for their excellent strength-to-weight ratio and corrosion resistance in these harsh downhole conditions.

Extracting oil and gas from miles beneath the Earth's surface is an incredible feat of engineering. It’s not just about drilling a deep hole; the pipes and tubes we use are the unsung heroes. They have to withstand immense pressures, corrosive fluids, and high temperatures. At SWA Forging, we've supplied aluminum components to various industries, and I've seen how material science is constantly pushing boundaries, even in sectors traditionally dominated by steel. The shift towards materials like high-strength aluminum for specific applications in oil and gas is fascinating. Let's explore the types of tubes that make this vital industry tick.

What Kind of Pipe is Typically Used in the Oil and Gas Industry?

The oil and gas sector needs pipes that won't buckle. Failures are costly and dangerous. So, selecting the right pipe material is absolutely critical.

The oil and gas industry uses various specialized pipes, including drill pipe for drilling, casing to secure the wellbore, tubing to transport product, and line pipe for overland transport. Materials range from carbon and alloy steels to, increasingly, aluminum alloys for specific needs.

When we talk about pipes in oil and gas, it's a broad category. Each type has a very specific job. I remember a project where a client needed a lightweight solution for a remote drilling operation, and that really highlighted how material choice impacts logistics, not just performance.

Here’s a quick rundown:

- Drill Pipe: This is the strong, heavy pipe that rotates the drill bit and circulates drilling fluid. Traditionally made of steel for its toughness.

- Casing: These are large-diameter pipes lowered into the wellbore and cemented in place. They provide structural integrity, prevent collapse, and isolate formations. Mostly steel.

- Tubing (Production Tubing): This is the pipe installed inside the casing through which oil or gas flows to the surface. Steel is common, but this is where materials like our 6061-T6 aluminum seamless tubes are finding more applications.

- Line Pipe: Used for transporting oil or gas over long distances, like in pipelines. Typically steel.

While steel has been the workhorse due to its strength and cost-effectiveness, the unique properties of aluminum alloys are making them attractive for certain applications. For example, the lighter weight of aluminum can significantly reduce the load on drilling rigs or make handling easier. Its corrosion resistance in specific environments is also a big plus. We've seen traders and machining companies show increasing interest in high-grade aluminum for these niche but important roles.

| Pipe Type | Primary Material | Key Characteristics | Emerging Material (Specific Cases) |

|---|---|---|---|

| Drill Pipe | Steel | High strength, torque resistance | Aluminum (components, lighter strings) |

| Casing | Steel | High collapse resistance, pressure integrity | Specialized composites (limited) |

| Production Tubing | Steel, Alloys | Pressure containment, corrosion resistance | 6061-T6 Aluminum (lightweight, corrosion) |

| Line Pipe | Steel | High strength, weldability, cost-effectiveness (large scale) | Composites (corrosion-prone areas) |

What Tubes Are Built to Transport Gas or Oil From the Well?

Getting oil or gas from deep underground to processing facilities is key. This transport needs specialized tubes. Leaks are not an option for safety or the environment.

Production tubing, typically made of steel or specialized alloys like 6061-T6 aluminum, transports oil or gas up the wellbore. For surface transport over distances, steel pipelines are primarily used.

Once oil or gas is found, we need a secure way to bring it to the surface and then move it to where it can be processed or used. This involves two main types of "transport tubes" within the broader oil and gas system. Downhole, inside the well, we use production tubing. This is the conduit that carries the hydrocarbons from the reservoir up to the wellhead. I recall a conversation with a machining customer who was fabricating custom connectors for production tubing; the precision required is immense.

Production tubing has to handle pressure from the reservoir, the weight of the fluid column, and potentially corrosive elements in the oil or gas. Traditionally, various grades of steel and corrosion-resistant alloys (CRAs) have been the go-to. However, as my insight noted, 6061-T6 aluminum seamless tubes are becoming more popular here. Their lighter weight can be a huge advantage in deep wells, reducing the load on the surface equipment and making them easier to run. Plus, aluminum’s natural corrosion resistance can be beneficial against certain downhole conditions, like CO2 if properly assessed.

Once at the surface, for longer distance transport, we rely on pipelines. These are the arteries of the energy industry, often spanning hundreds or thousands of miles. These are almost exclusively made of steel due to the volume of material needed and the strength requirements for high-pressure, large-diameter lines. While SWA Forging focuses on aluminum, understanding the role of steel pipelines helps frame where our specialized aluminum products fit into the bigger picture.

What Exactly Are Petroleum Pipelines?

We hear about pipelines, but what are they really? These vast networks are critical infrastructure. Understanding them shows how energy moves across continents.

Petroleum pipelines are extensive systems of interconnected pipes, primarily made of high-strength steel. They are designed for the long-distance transportation of crude oil, refined petroleum products, and natural gas efficiently and safely.

Petroleum pipelines are the workhorses for moving large volumes of oil and gas over land, and sometimes even under the sea. Think of them as specialized highways for energy. When I first learned about the scale of some pipeline projects, I was amazed by the engineering involved. These aren't just simple pipes; they are complex systems.

There are different types:

- Gathering Pipelines: Smaller lines that collect oil or gas from multiple wells and transport it to a central processing facility or a larger transmission line.

- Transmission Pipelines: These are the big ones – large-diameter, high-pressure pipelines that transport oil, gas, or refined products over long distances, often between regions or countries.

- Distribution Pipelines: These take natural gas from the transmission system and distribute it to local consumers, like homes and businesses.

The primary material for these pipelines is steel, specifically grades like API 5L, designed for high strength, toughness, and weldability. They are often coated externally to prevent corrosion and may also have cathodic protection systems. While aluminum isn't typically used for the main body of these large pipelines due to scale and the specific mechanical properties needed, components within pumping stations or related equipment might use specialized aluminum alloys. Our focus at SWA Forging with materials like 6061 aluminum forging tubes is more on the downhole applications or specialized equipment rather than the massive pipeline networks themselves.

What Does "Tubing" Mean Specifically in Oil and Gas Operations?

The term "tubing" can be general. But in oil and gas, it has a precise meaning. Its integrity is vital for bringing reserves to the surface.

In the oil and gas industry, "tubing" refers to the specific pipe placed inside the well's casing. Its primary function is to convey oil or gas from the producing formation up to the wellhead at the surface.

This is where my insight about 6061-T6 aluminum seamless tubes really comes into play. In the oilfield, when someone says "tubing," they almost always mean production tubing. It's distinct from drill pipe (used for drilling) and casing (which lines the wellbore). Production tubing is the final pathway for the oil or gas to flow out of the ground. I've worked with clients who are machining specialized end-fittings for these tubes, and the tolerances are critical because they have to ensure a perfect, pressure-tight seal.

Traditionally, production tubing has been made from various grades of carbon steel or more expensive corrosion-resistant alloys (CRAs) if the well fluids are particularly nasty (e.g., high in H2S or CO2). However, steel is heavy. In very deep or highly deviated wells, the sheer weight of a steel tubing string can be a major issue, putting a lot of stress on the rig and equipment. This is where 6061-T6 aluminum seamless tubes are making significant inroads.

Key advantages of 6061-T6 aluminum in this application include:

- Light Weight: Aluminum is about one-third the density of steel. This means a significantly lighter tubing string, which is easier to handle, transport, and install. It can also allow for smaller, less powerful rigs in some cases.

- Corrosion Resistance: 6061 aluminum has good resistance to certain corrosive environments found in oil and gas wells, particularly CO2. This can extend the life of the tubing and reduce the need for expensive inhibitors or frequent replacements.

- Strength: The -T6 temper means the 6061 aluminum has been solution heat-treated and artificially aged, giving it excellent strength properties, suitable for many downhole pressure environments.

- Seamless Construction: Seamless tubes, which SWA Forging specializes in producing, don't have welds, which can be points of weakness. This offers better pressure integrity.

Of course, aluminum isn't a universal replacement. It has lower temperature limits than steel and might not be suitable for highly abrasive conditions or certain extremely corrosive environments without careful assessment. But for many applications, particularly where weight is a concern or moderate corrosion resistance is needed, 6061-T6 aluminum tubing is an increasingly smart choice. We ensure our aluminum products meet rigorous quality standards, backed by certifications like ISO9001, because in deep well exploration, there's no room for error.

Conclusion

Deep well exploration relies on advanced tubing. While steel remains a staple, 6061-T6 aluminum seamless tubes provide key benefits like lighter weight and corrosion resistance for specific, demanding oil and gas applications.