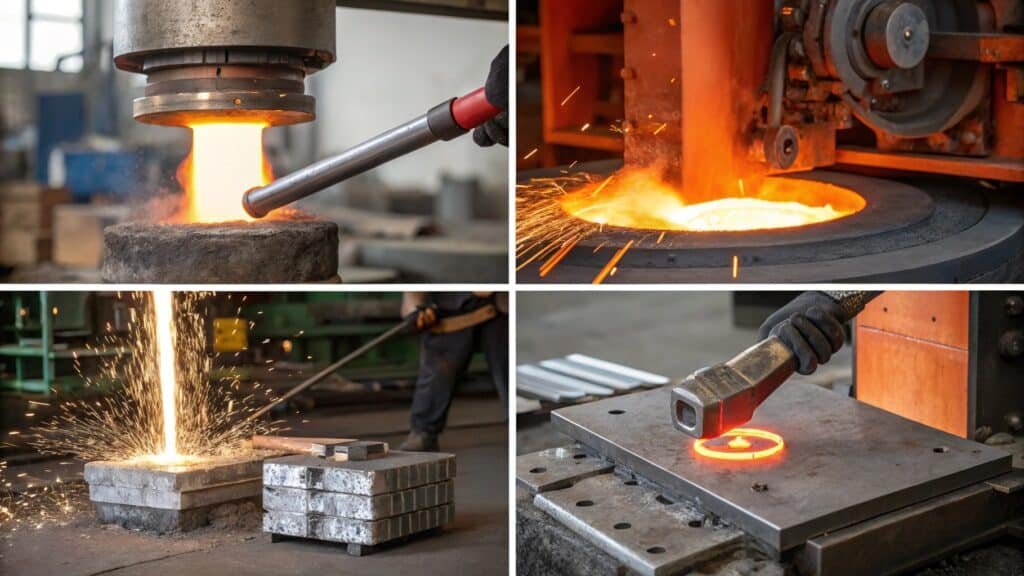

Are you curious about how strong, precisely shaped metal parts are made? Forging is a fundamental process that creates high-quality components, but understanding its various types can be complex.

Forging is a manufacturing process that shapes metal using localized compressive forces, resulting in strong, reliable parts with excellent grain structure.

Let's break down what forging is, its different types, and why it remains a vital manufacturing technique today.

What are the four forging operations?

Wondering about the specific steps that happen during a forging process? Understanding these operations clarifies how metal is shaped.

The four main forging operations are preforming, blocking, finishing, and trimming, each serving a distinct purpose in shaping the metal into its final form.

Forging isn't just a single action; it's a series of carefully controlled steps designed to transform a raw piece of metal into a precise component. The first operation is preforming. This step modifies the initial workpiece, often by upsetting or drawing it out, to prepare it for the subsequent shaping stages. It helps distribute the material more evenly, reducing the amount of work needed in later stages and preventing defects. Next is blocking. In this operation, the workpiece is shaped into a form that closely resembles the final part but is not yet fully detailed. Blocking dies are used to create the basic contours and features, progressively bringing the metal closer to its intended geometry. This stage is critical for guiding the metal's flow and establishing the grain structure. Following blocking is the finishing operation. Here, the part is passed through a final set of dies that impart the precise dimensions, sharp details, and smooth surface finish required for the finished product. This is where the part truly takes its final shape and meets all specifications. The last essential operation is trimming. After the finishing die has shaped the part, some excess material, known as flash, is often squeezed out between the die halves. Trimming involves cutting away this excess flash, leaving a clean, finished part. My team ensures each of these operations is performed with exact precision to guarantee the quality of our forged aluminum products.

What are the three main categories of metalworking processes?

Confused about how forging fits into the broader landscape of shaping metals? Understanding the main categories helps place forging in context.

The three main categories of metalworking processes are forming, cutting, and joining, with forging falling under the forming category.

Metalworking encompasses a vast array of techniques used to shape and assemble metals. These techniques can be broadly classified into three primary categories: forming, cutting, and joining. Forming processes, like forging, involve changing the shape of a metal workpiece without removing material. Instead, force is applied to deform the metal, often by leveraging its plasticity. This category includes operations such as rolling, drawing, extrusion, stamping, and, of course, forging. Forming processes are highly valued for their ability to refine grain structures and enhance the mechanical properties of metals. Cutting processes, on the other hand, involve removing material to achieve a desired shape or size. This includes machining operations like turning, milling, drilling, and sawing, as well as shearing and abrasive cutting. Joining processes are used to connect two or more pieces of metal together. This category includes welding, brazing, soldering, and mechanical fastening methods like riveting or bolting. Forging is a cornerstone of the forming category because it directly manipulates the metal's shape through applied force, leading to parts with superior integrity. We specialize in forming, specifically through forging, to deliver the highest quality aluminum components.

What are the two methods of forging metal?

Wondering about the different ways metal can be forged? Knowing the basic methods helps understand the versatility of this process.

The two primary methods of forging metal are open-die forging and closed-die forging.

The fundamental distinction in forging lies in how the metal is contained and shaped by the dies. The two main methods are open-die and closed-die forging1. In open-die forging2, the workpiece is placed between flat or very simple shaped dies. As the hammer or press strikes the metal, it's free to spread outwards. This method is often used for simpler shapes, like bars, rods, or discs, and for smaller production runs. It requires significant skill to manually manipulate the workpiece and achieve the desired shape. While it offers flexibility, it generally results in less precise dimensions and a rougher surface finish compared to closed-die forging. Closed-die forging, also known as impression-die forging, involves dies with cavities that precisely match the final shape of the part. The heated metal is placed in the lower die, and the upper die closes down, forcing the metal to fill the cavity. This method is ideal for producing complex shapes with high accuracy and excellent repeatability, often requiring less secondary machining. My work at SWA Forging primarily focuses on closed-die forging because our clients, particularly in the Middle East, demand high precision and consistent quality for their critical components.

Here’s a comparison of the two forging methods:

| Feature | Open-Die Forging | Closed-Die Forging |

|---|---|---|

| Die Design | Flat or simple shaped dies. | Dies with precise cavities matching the part shape. |

| Material Flow | Metal spreads freely. | Metal is confined to fill the die cavity. |

| Complexity | Best for simpler shapes (bars, rods, rings). | Ideal for complex shapes with intricate details. |

| Accuracy | Lower dimensional accuracy, rougher surface finish. | High dimensional accuracy, smooth surface finish. |

| Production Volume | Suitable for smaller runs and prototypes. | Economical for large-volume production. |

| Material Use | Can have more material waste (flash). | More efficient material utilization, less flash. |

Is forging still used today?

Wondering if forging3 is an outdated technique or if it's still relevant in modern manufacturing? The answer might surprise you.

Yes, forging is absolutely still used today and remains a critical manufacturing process for producing high-strength, reliable metal components across numerous industries.

Despite the advent of advanced manufacturing technologies, forging continues to be indispensable in modern industry. Its primary advantage lies in the superior mechanical properties it imparts to metal parts. By refining the grain structure and ensuring continuous grain flow, forged components exhibit exceptional strength, toughness, fatigue resistance, and ductility. These characteristics are vital for parts subjected to high stress, impact, or cyclic loading. Industries like aerospace, automotive, defense, energy, and heavy machinery rely heavily on forged components such as crankshafts, connecting rods, gears, turbine blades, and structural aircraft parts. The precision offered by modern closed-die forging, combined with advanced materials, allows for the creation of highly complex and lightweight parts that meet stringent performance requirements. At SWA Forging, we see the demand for forged aluminum parts grow as industries increasingly seek materials that offer a high strength-to-weight ratio and proven reliability. Far from being obsolete, forging is a cornerstone of high-performance manufacturing, continuously evolving with new technologies and materials.

Conclusion

Forging shapes metal using localized forces, with two main types: open-die and closed-die, supported by operations like preforming and finishing, and remains vital for high-strength components today.

-

Discover the precision and repeatability of closed-die forging, ideal for complex shapes and high-quality components. ↩

-

Understand open-die forging's flexibility and applications, especially for simpler shapes and smaller production runs. ↩

-

Explore how forging remains a vital process in manufacturing, ensuring high-strength components across various industries. ↩