Are you unsure if open die forging1 is the right choice for your aluminum components? Let us guide you through the process.

Open die forging is ideal for large, custom-shaped aluminum parts where flexibility, cost-effectiveness, and enhanced material properties are paramount, offering significant advantages over other methods for specific applications.

Clients often come to us with specific needs for aluminum components, and a key part of our discussion involves determining the most suitable manufacturing method. Open die forging is a process we frequently recommend for its unique capabilities, especially when dealing with large or custom-sized parts.

When selecting materials for forging, what is the most important factor?

Selecting the right material is the first and most critical step in any forging project, as it dictates the final part's performance and suitability for its intended application.

When selecting materials for forging, the most important factor is matching the material's inherent properties—such as strength, ductility, corrosion resistance, and heat treatability—to the specific demands and operating environment of the intended application.

Understanding material selection is fundamental to successful forging. Our experience at SWA Forging shows that a deep understanding of the application's requirements is essential for choosing an aluminum alloy2 that will perform optimally and reliably.

Here's why material selection is paramount:

- Application Requirements: The primary driver is the end-use of the component. Does it need high strength for structural integrity, excellent corrosion resistance for marine environments, good electrical conductivity, or specific thermal properties?

- Formability and Processability: The chosen material must be capable of being forged into the desired shape without cracking or excessive difficulty. Some alloys are more ductile and easier to form than others.

- Mechanical Properties: The material's tensile strength, yield strength, hardness, ductility, and toughness must meet or exceed the performance criteria for the application.

- Heat Treatment Response: If the final part requires enhanced properties through heat treatment (like the T6 temper), the chosen alloy must respond effectively to these processes.

- Cost and Availability: While performance is key, the cost and availability of the raw material also play a role in the overall project feasibility.

Ultimately, the "most important factor" is a holistic consideration of how the material's intrinsic qualities align with the rigorous demands of the final application.

What are the advantages of impression die forging?

Impression die forging, also known as closed die forging, offers distinct benefits, particularly for components requiring precision and uniformity.

Impression die forging (closed die forging) offers advantages such as creating parts with complex shapes and intricate details, achieving tight dimensional tolerances, excellent surface finish, and enabling high-volume production with consistent quality, all while enhancing the material's inherent strength.

Clients often ask about the benefits of different forging techniques. Impression die forging, or closed die forging, is known for its precision and its ability to replicate complex geometries accurately and efficiently across many parts.

Here are the key advantages of impression die forging:

- Complex Shapes: The dies have impressions that precisely shape the metal, allowing for the creation of intricate designs, features like ribs, bosses, and undercuts, which are difficult or impossible with other methods.

- High Dimensional Accuracy: The enclosed dies guide the material flow precisely, resulting in parts with very accurate dimensions and excellent surface finishes. This often reduces the need for extensive post-forging machining.

- Enhanced Material Properties: Similar to open die forging, the process refines the grain structure of the metal, aligning it with the contours of the die. This leads to superior strength, ductility, and fatigue resistance compared to casting or machining.

- High-Volume Production: Once the significant tooling investment is made, impression die forging is highly efficient for producing large quantities of identical parts with minimal variation.

- Improved Surface Finish: The smooth surfaces of the dies help create a good surface finish on the forged part, often requiring less secondary finishing work.

These advantages make impression die forging an ideal choice for many critical components in demanding industries.

What are the applications of open die forging?

Open die forging is a versatile process, particularly well-suited for producing a wide range of large, custom, or simpler aluminum components.

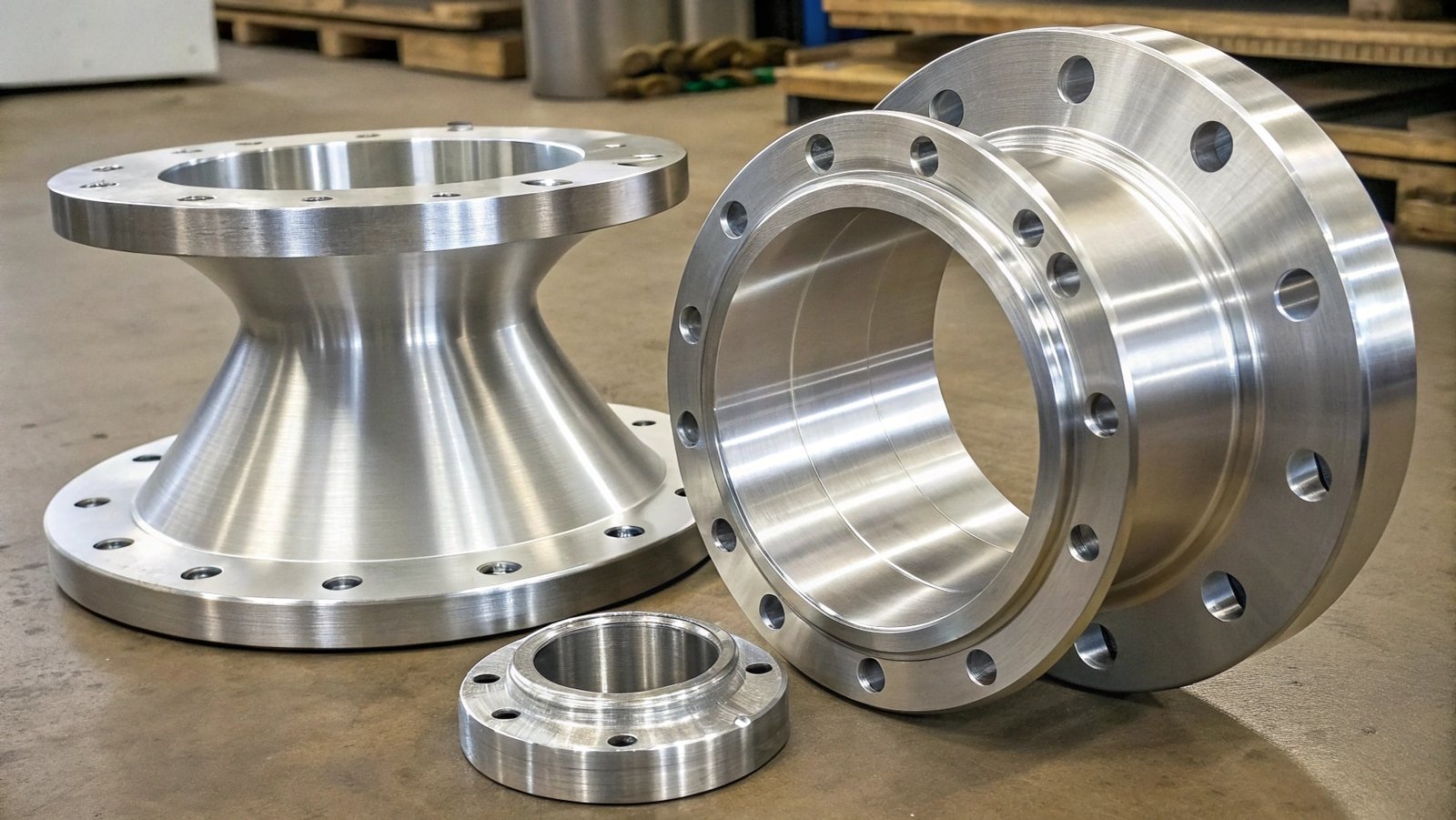

The applications of open die forging are diverse, including the production of large rings for industrial equipment, custom-sized discs and plates for manufacturing, shafts for machinery, and various custom-shaped components where precision is less critical than size flexibility and enhanced material properties.

When we discuss our forging capabilities, the applications of open die forging are often a key focus. Its flexibility allows us to serve a broad spectrum of industries with parts that might be too large or too custom for other methods, while still benefiting from the inherent strengths of the forging process.

Here are common applications for open die forging:

- Large Industrial Rings: These are crucial for components in machinery, pipelines, pressure vessels, and even aerospace applications where large, precise rings are needed.

- Custom Discs and Plates: For various manufacturing and engineering purposes, custom-sized discs and plates with specific dimensional requirements are often produced using open die forging.

- Shafts and Rods: Long, cylindrical parts or shafts with specific cross-sections needed for machinery, automotive components, or industrial equipment can be effectively made through this process.

- Custom Shapes and Prototypes: When a unique shape is required, especially for large components or for initial product development, open die forging's flexibility and lower tooling costs make it an excellent choice.

- Flanges and Bushings: While some flanges and bushings can be made via closed die, larger or simpler versions are well-suited for open die forging.

- Tooling Components: For larger tools or components that require high strength and durability, open die forging can provide the necessary material integrity.

The versatility of open die forging allows us to cater to a broad range of client needs across many different sectors.

Which is not ideal for forging?

While forging is a powerful manufacturing process, certain materials or design requirements are not ideally suited for it.

Materials that are extremely brittle, have very low melting points, or exhibit poor ductility at forging temperatures are not ideal for forging. Additionally, parts with extremely intricate internal geometries, very thin walls, or those requiring low-volume production of complex shapes might be better suited for other manufacturing methods like casting or machining.

It’s important to understand the limitations of any manufacturing process. When discussing forging, there are certain materials and part designs that don't lend themselves well to the process, and it’s our role to help clients identify these scenarios to avoid wasted resources and ensure the best outcome.

Here are some examples of what is not ideal for forging:

- Extremely Brittle Materials: Materials that cannot withstand significant plastic deformation without fracturing are unsuitable for forging. Their inherent brittleness would lead to cracking under the stresses of the forging process.

- Very Low Melting Point Metals: While aluminum has a relatively low melting point compared to steel, some metals melt at temperatures too close to their forging temperatures, making the process difficult to control.

- Materials with Poor Ductility at Forging Temperatures: If a material becomes too brittle or too weak at the temperatures required for forging, it cannot be effectively shaped.

- Parts with Very Complex Internal Cavities: While external shapes are well-defined, creating intricate internal passages or hollows solely through forging can be extremely difficult or impossible without extensive secondary operations.

- Very Thin-Walled Sections: Forging requires sufficient material thickness to withstand the forces and to form the shape without thinning too much and potentially tearing. Very thin-walled parts are often better produced by machining or sheet metal fabrication.

- Low-Volume, Highly Complex Parts: For parts that are both highly complex in shape and only needed in very small quantities, the high cost of custom forging dies (especially for closed die) may make machining or additive manufacturing more economical alternatives.

- Highly Porous Materials: Materials that are inherently porous and cannot achieve the necessary density and structural integrity through deformation are not suitable for forging.

Identifying these limitations helps ensure that we recommend the most appropriate and cost-effective manufacturing solution for every client’s unique project.

Conclusion

Choosing the right forging method at SWA Forging depends on your aluminum part's needs. Open die forging is excellent for large, custom pieces with simpler shapes, while impression (closed die) forging excels at high-volume, complex parts requiring precision. Forging generally produces stronger parts than casting, but its suitability is limited by material properties and design complexity.